NX for Manufacturing

Drive efficient end-to-end part manufacturing operations and deliver high-precision parts through digitalization.

Program CNC machine tools, control robotic cells, drive 3D printers and monitor quality using one software system. Digitally transform your part manufacturing business to gain productivity and increase profitability.

NX CAM

Program any job using one software. NX CAM provides comprehensive and integrated NC programming capabilities in a single system. This enables the use of consistent 3D models, data and processes to seamlessly connect planning and shop floor operations with a digital thread.

You can streamline and automate NC programming, while reducing cycle time, using powerful, application-specific tools. From 2.5-axis machining and mold manufacturing, to simultaneous 5-axis milling and high-volume production, NX allows you to use one CAM software to make better parts faster.

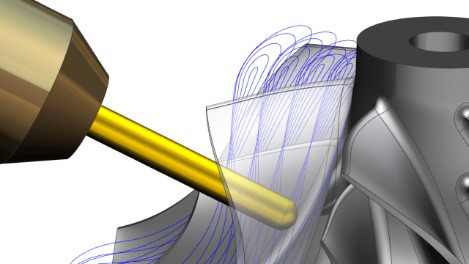

Complex Parts Machining

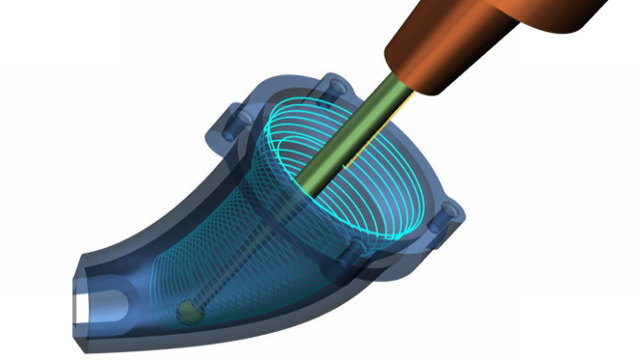

With 5-axis machining, you can produce complex parts with fewer operations and setups – reducing cost and delivery times. NX CAM’s 5-axis capabilities allow you to create precisely controlled tool paths to effectively machine complicated geometries.

The software’s application-specific capabilities can dramatically simplify programming of the most complex parts, such as impellers, blisks, and engine ports. You can create optimized operations and eliminate errors in production by visualizing multi-axis toolpath characteristics.

Create Advanced 5-axis Operations

NX CAM offers a range of advanced 5-axis methods with a precise control of the tool-axis and automated collision avoidance. For example, the variable-axis profiling requires only minimum geometry selection to cut along drafted walls using the side of the cutter.

The latest 5-axis cutting strategies facilitate high-speed finishing that follow the natural shape of the part, reducing machining time and improving surface finish.

Barrel tools, which feature large cutting edge radius, allow larger tool’s engagement with the material to increase multi-axis machining efficiency and part quality

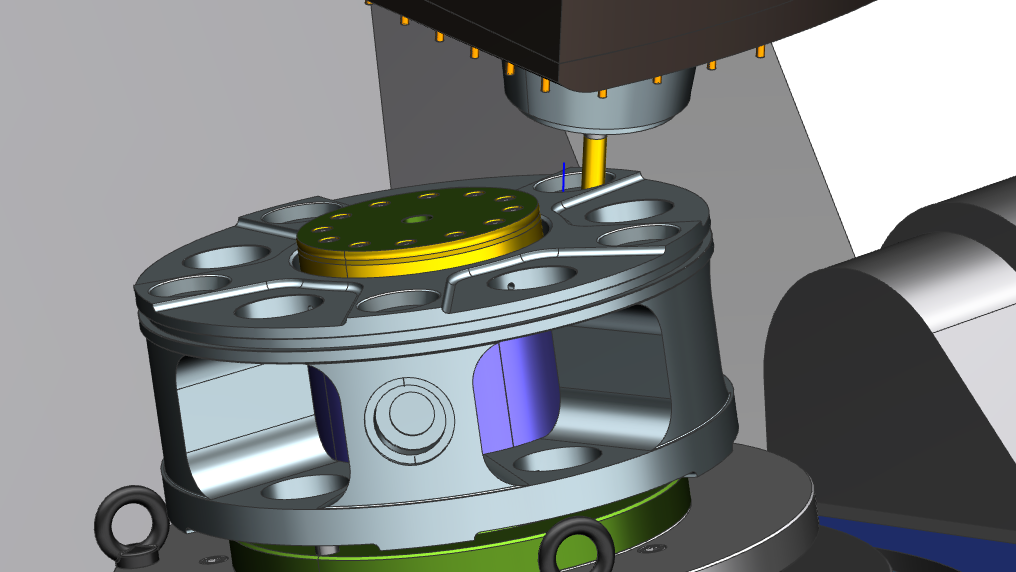

Program Multi-Blade Parts Using Turbomachinery Milling

Specialized 5-axis NC programming operations helps you reduce effort to program complex multi-bladed rotational parts, such as blisks and impellers.

Simultaneous 5-axis roughing and automated rest milling enables efficient material removal between the blades. Specialized finishing operations for the hub, blades, and spliters helps you create optimized tool path by precisely controlling cut patterns and tool path smoothing, as well as tool axis stabilization parameters for the edges.

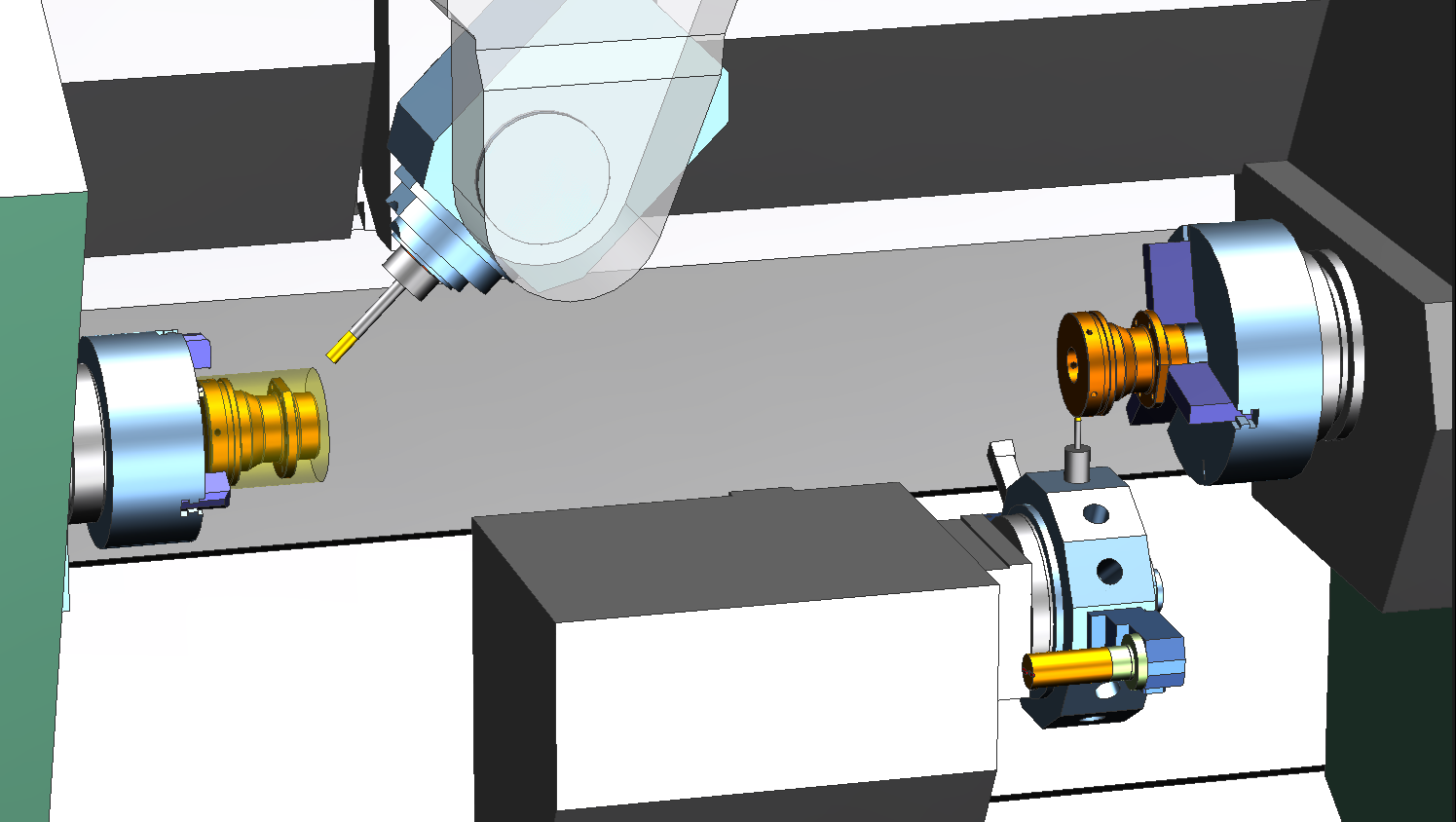

Postprocessing & Machining Simulation

Generate NC programs for a wide range of CNC machine tools with NX’s integrated postprocessor. The machine-ready NC programs enable you to increase machine tool utilization and overall production efficiency.

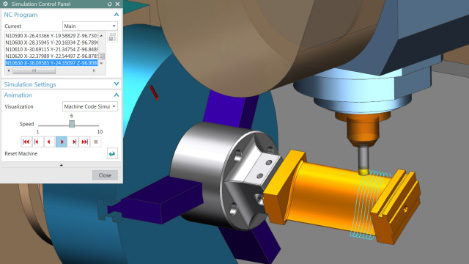

Leverage the digital twin of your machines and entire production lines to validate operations before you start the production. By using the integrated G-code-driven machine simulation in NX CAM you can optimize manufacturing processes and eliminate errors on the shop floor.

Validate Machining Processes

A key NX CAM advantage facilitates integrated simulation and verification, enabling you to validate tool paths within the NC programming session.

Multiple levels of capability are available. For example, material removal verification enables you to check and optimize the machining operations as you program.

The G-code-driven machine tool simulation displays the motion driven from the NC code output of the NX internal postprocessor. A 3D model of the machine – with the part, fixtures and tooling – moves in the way the machine tool will move as the G-code is processed.

For advanced machine tools, support kits provide a complete solution that includes:

- Proven postprocessor

- 3D digital model of the machine tool

- Machine Ready NX Programs.

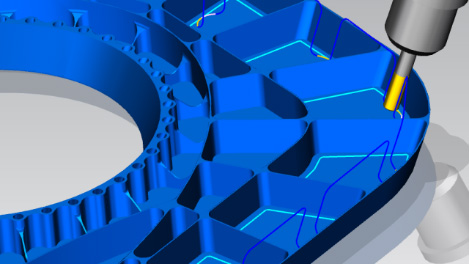

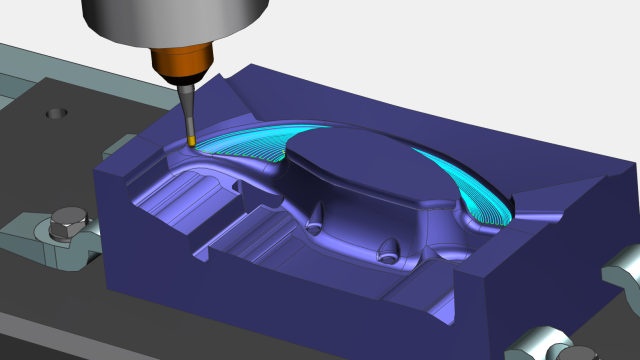

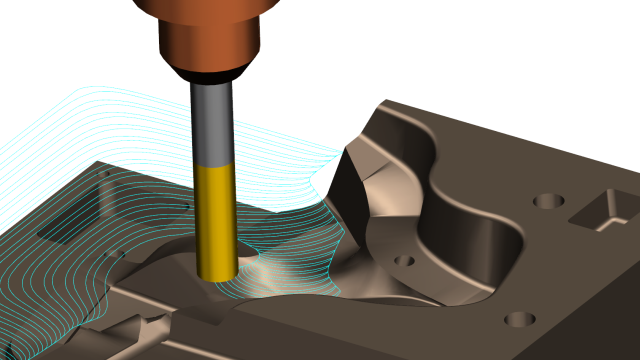

Die & Mold Machining

Make better molds, dies, and electrodes using a single software system. NX CAM advanced capabilities for high-speed machining, automated rest milling, and smooth finishing methods help you produce high-quality tooling faster.

You can further reduce lead time and improve quality using specialized, easy-to-use five-axis machining capabilities for mold and die machining.

Using the digital twin of your machine setup, you can validate the machining process to eliminate errors on the shop floor.

Manufacture Mold Inserts with Excellent Finish

You can further reduce lead time and improve quality using specialized, easy-to-use five-axis machining capabilities for mold and die machining.

Using the digital twin of your machine setup, you can validate the machining process to eliminate errors on the shop floor.

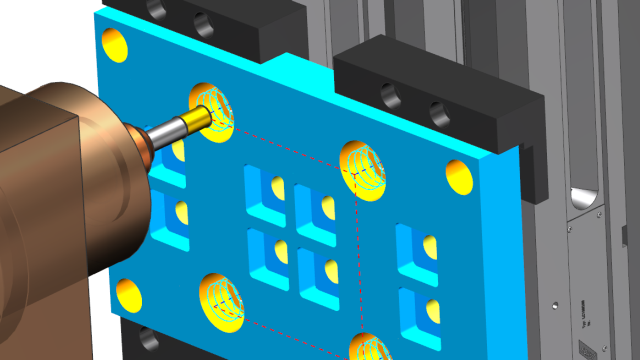

Program Mold Bases Automatically

Programming mold bases with a large number of machining features, such as holes, pockets, and slots can be very time consuming and error-prone. You can automate the programming process using NX CAM feature-based machining (FBM). It automatically recognizes features and applies the right cutting operations, improving repeatability and reducing NC programming time by up to 90 percent.

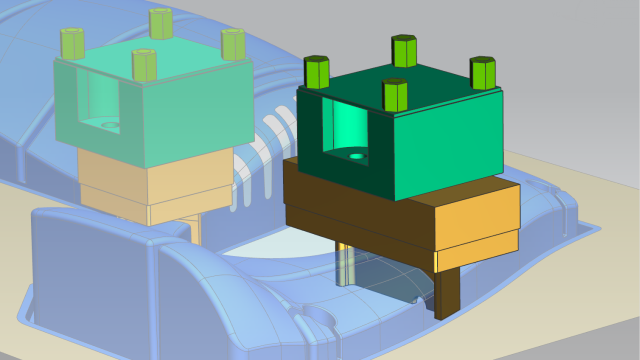

Automate Electrode Manufacturing

Electrode manufacturing is an important step in the development process of tooling that requires use of electrical discharge machining (EDM).

Integrated electrode design and NC programming capabilities in NX helps you accelerate the production of electrodes of any complexity.

Using a range of advanced cutting strategies such as high-speed finishing, you can quickly machine smooth and accurate electrodes. Our step-by-step solution lets you automate the entire process from design through production – reducing time and production costs.

Associativity between the part model, mold and electrodes designs, allows you to easily update machining operations to accommodate engineering change orders.

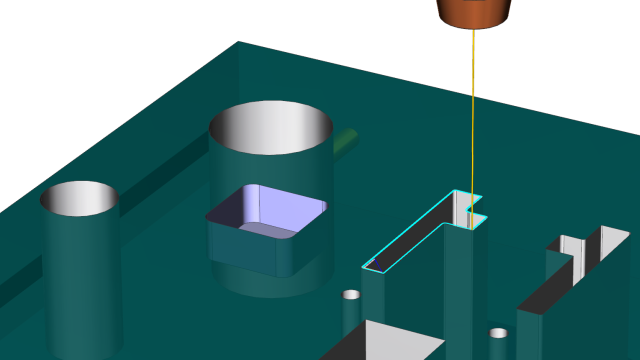

Wire EDM operations

Wire EDM operations that are used for manufacturing of mold bases, electrodes, and related components improve part quality and reduce the total number of manufacturing steps. NX CAM provides a comprehensive set of 2- and 4-axis wire EDM operations including multi-pass profiling, wire reversing, and area removal.

You can automate the programming of wire EDM machines by using feature-based machining (FBM).

Additive Manufacturing

Siemens NX provides all of the necessary capabilities, from design to print to post-print validation, in a single integrated system. Siemens NX is industrializing additive manufacturing so you can not only prototype, but also manufacture ground-breaking products with this exciting new technology.

This allows you to reimagine your products, reinvent your manufacturing and even rethink your business models with additive manufacturing technology.

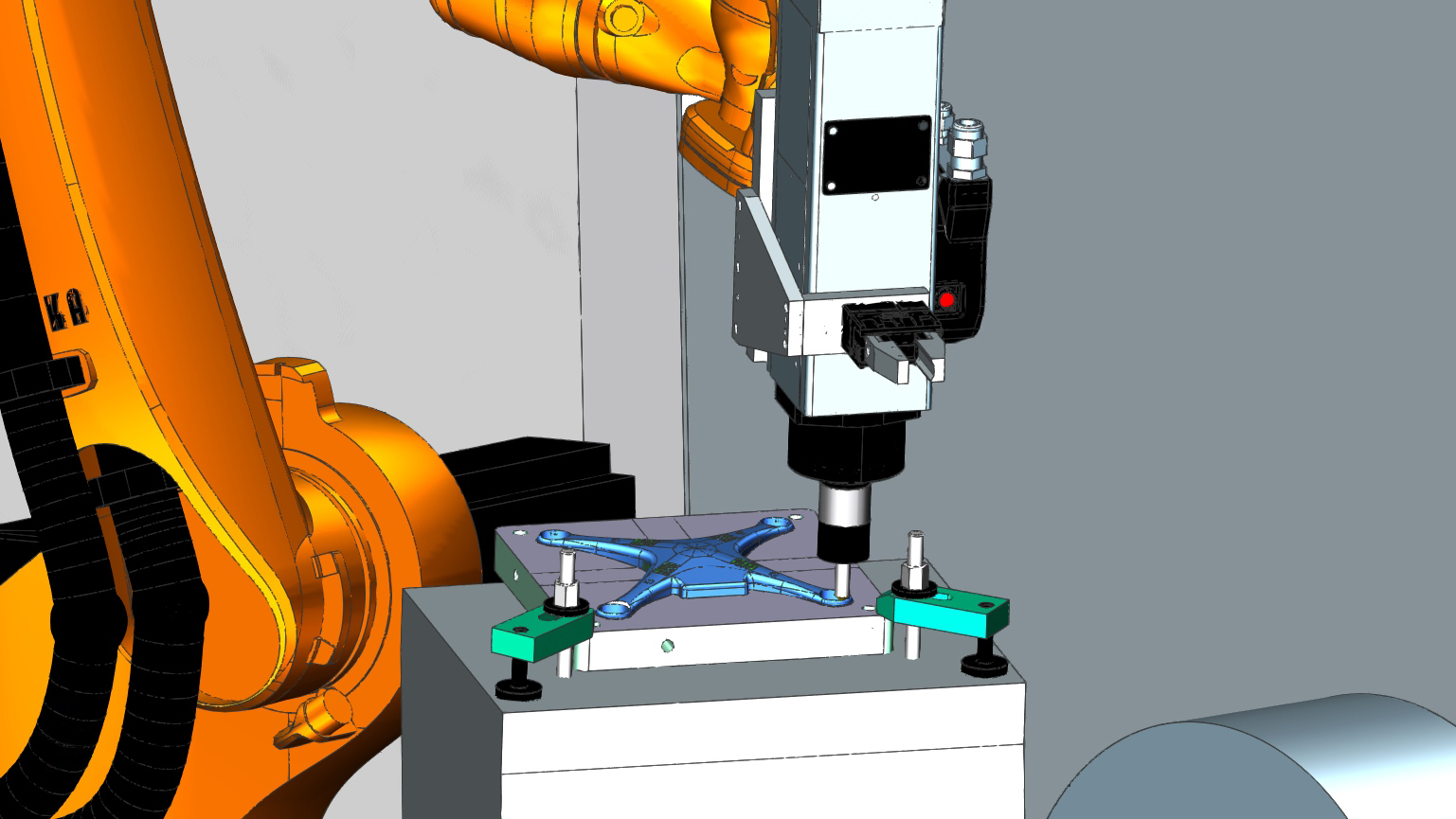

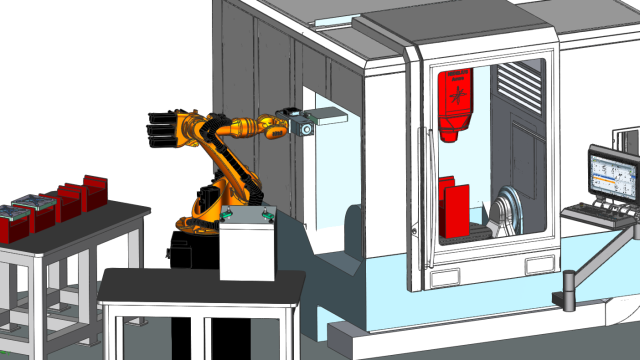

Robotic Automation

Advanced robotics can improve your productivity by automating your part manufacturing operation – from a blank to a finished part.

Robotic machining provides more flexibility that can dramatically improve efficiency on the shop floor. Using NX CAM, you can program robots to machine large parts and to automate machining tasks typically performed manually.

- Program Robots for Pick & Place Operations.

- Use Robots to Automate complete Production Work cell Automation.

- Program robots to perform precise machining tasks such as trimming, de-burring, grinding, and polishing

NX CAM - Part Manufacturing Solution

Siemens PLM Software provides a complete part manufacturing solution – from NX CAM to machine tool controller.