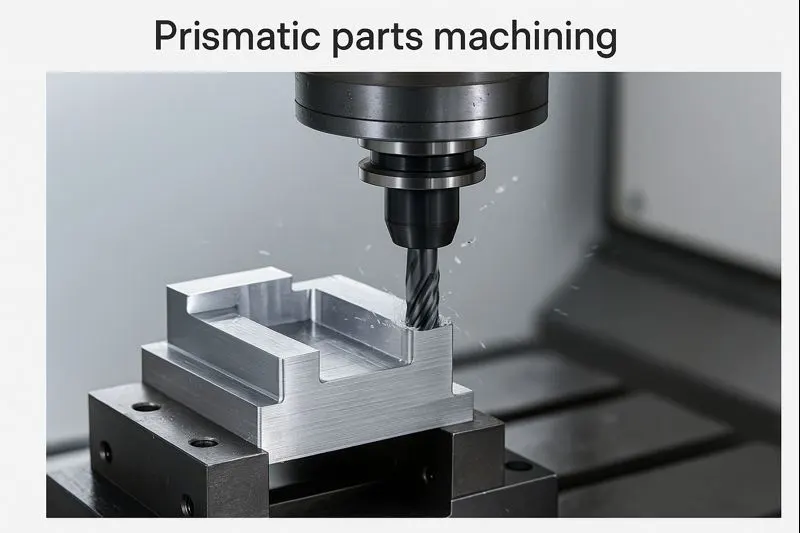

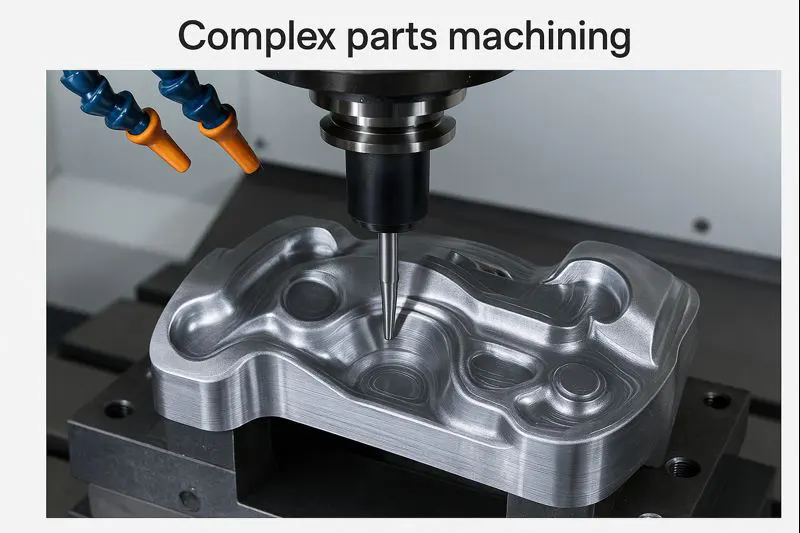

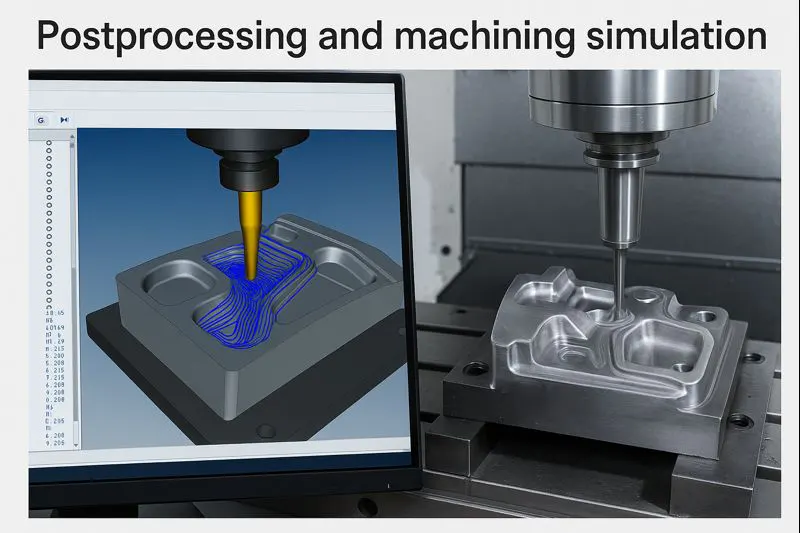

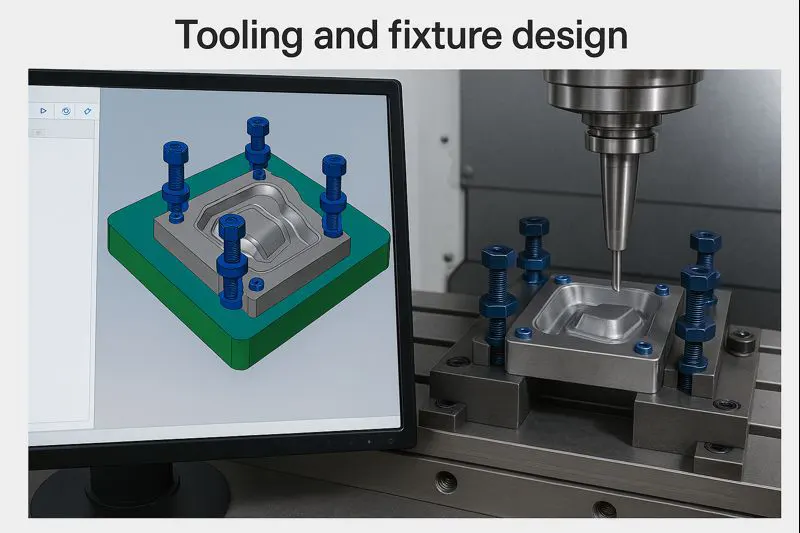

NX CAM is a comprehensive, industry-proven SIEMENS CAM solution that supports CNC programming, machining simulation, postprocessing, and manufacturing validation within a single integrated environment. Built on the same platform as NX CAD, SIEMENS NX CAM enables a true digital thread from design to manufacturing without data translation, ensuring accuracy, associativity, and engineering continuity.

NX CAM is widely used across automotive, aerospace, mold and die, tooling, medical devices, and industrial machinery industries. Its scalability allows manufacturers to start with basic milling and expand to advanced multi-axis, mill-turn, and high-speed machining as business requirements evolve.