Simcenter software combines system simulation, 3D CAE and test to help you predict performance across all critical attributes earlier and throughout the entire product lifecycle. By combining physics-based simulations with insights gained from data analytics, Simcenter helps you optimize design and deliver innovations faster and with greater confidence.

Simcenter

Simcenter lets you predict performance of your 3D geometry based designs. In our Simcenter 3D CAE products, you can import geometry from any CAD source and prepare analysis models in a unified environment for a wide range of CAE methods including finite element, boundary element, computational fluid dynamics, and multi-body dynamics.

Simcenter STAR-CCM+

To accurately predict real-world performance of your product you need simulation tools that capture all of the physics that will influence its performance during its operational life, including those that cross the boundaries of traditional engineering disciplines. To improve your product you need to be able to predict how performance changes in response to multiple parametric design changes.

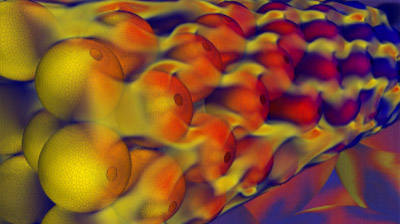

Fluid dynamics simulation

Since the real-world performance of your product depends on how it interacts with fluids, either gases, liquids or a combination of both, you need to predict how those fluids behave, and to be able to turn their influence to your product’s advantage.

Simcenter provides industry leading computational fluid dynamics software that allows you to simulate almost any engineering problem that involves the fluids, structures and all of the associated physics.

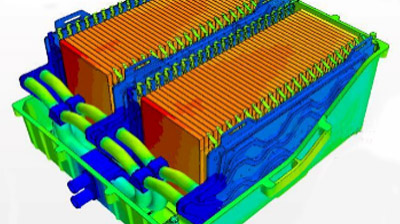

Battery Simulation

Digitally validate Li-ion cell design including geometrical cell specifications and cell performance. Extensive components of a battery cell are available, as well as a material database to support the user in its model development.

Design Exploration

Rather than just simulating a single operating point, explore how your product performs over the full range of operating conditions that it will face during its working life, and employ intelligent design exploration to discover better designs faster.

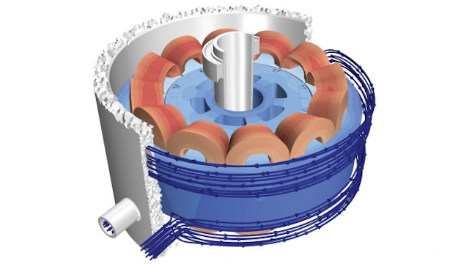

Electric Machines

Comprehensive analytical models include all aspects of the design of electric machines, including thermal, electromagnetic and drive control. Of particular importance is the efficient utilization, and even elimination, of magnets. Our simulation tools are structured to give seamless design capability over the entire range of permanent-magnet machines and the alternatives including hybrid combinations and covers the entire range of power, voltage, and speed used in vehicle systems.

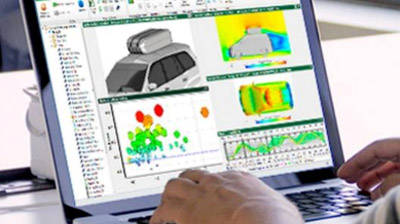

Simcenter Testing

In the digital era, it remains crucial to test, validate and optimize real-world designs within the constraints of shorter testing cycles, conflicting performance requirements, growing product complexity and reduced costs.

In the digital era, it remains crucial to test, validate and optimize real-world designs within the constraints of shorter testing cycles, conflicting performance requirements, growing product complexity and reduced costs.

Enhance testing processes and boost productivity and product innovation with Simcenter Testing Solutions. Our solutions integrate multiphysics data acquisition hardware with a complete suite of acquisition, analytics and modeling software to cover a wide range of test needs.

Simcenter Testing Solutions deliver critical insights for innovate smart products, increase testing productivity and efficiency, maintain quality, enhance team collaboration and engineering flexibility, close the loop with simulation and lower cost of ownership..

Frequently Asked Questions

What is NX CAE?

NX CAE is a powerful computer-aided engineering software that provides tools for simulation and analysis of product designs.

What types of analysis does NX CAE support?

NX CAE supports various types of analysis including structural, thermal, fluid flow, and motion analysis, among others.

Can NX CAE perform linear and nonlinear analysis?

Yes, NX CAE can perform both linear and nonlinear analysis to simulate the behavior of components and assemblies under different loading conditions.

Does NX CAE support optimization studies?

Yes, NX CAE includes optimization tools to help engineers improve product performance, reduce weight, and optimize designs based on specified criteria.

Is NX CAE integrated with NX CAD?

Yes, NX CAE is fully integrated with NX CAD, allowing engineers to seamlessly transfer design data for analysis and simulation.

Can NX CAE simulate real-world operating conditions?

Yes, NX CAE enables engineers to simulate real-world operating conditions such as temperature variations, fluid flow, and dynamic loads to evaluate product performance.

Does NX CAE offer fatigue analysis capabilities?

Yes, NX CAE includes fatigue analysis tools to assess the durability and lifespan of components subjected to cyclic loading conditions.

Are training programs available for NX CAE users?

Yes, SIEMENS PLM Software offers training programs and resources for NX CAE users to learn simulation techniques and best practices.

What industries typically use NX CAE?

NX CAE is used across industries such as automotive, aerospace, consumer products, and heavy machinery for virtual testing and validation of product designs.

Can NX CAE perform frequency and modal analysis?

Yes, NX CAE can perform frequency and modal analysis to determine natural frequencies, mode shapes, and dynamic behavior of structures under vibration loads.