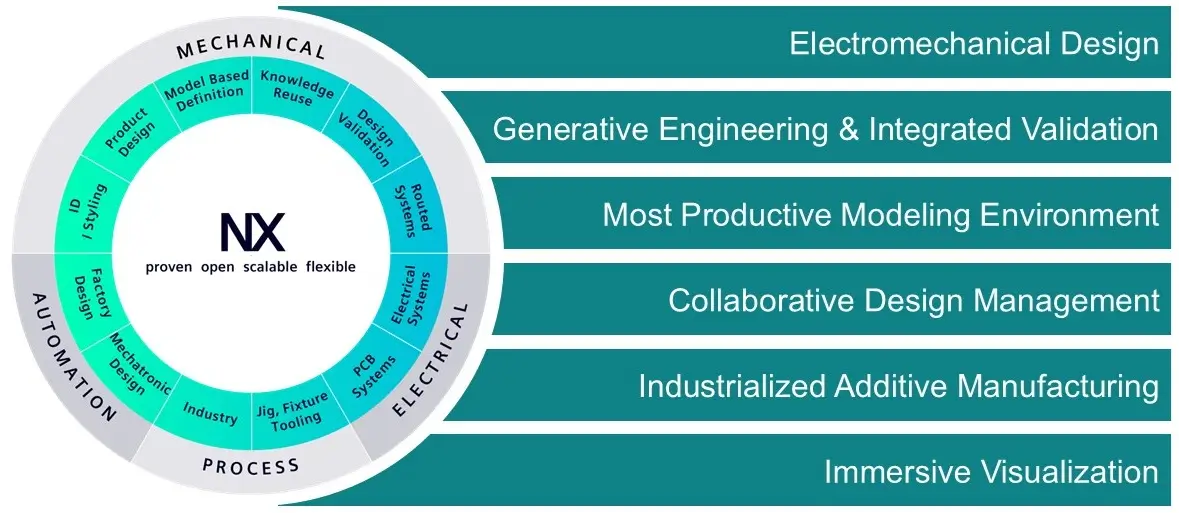

SIEMENS NX CAD is one of the world’s most advanced engineering platforms, combining mechanical design, electrical collaboration, simulation, AI-driven intelligence, immersive visualization, and automation into a single unified environment. It allows organisations to design faster, validate earlier, and innovate confidently, ultimately transforming engineering operations into a streamlined, digitally connected workflow.

The key capabilities that make SIEMENS NX CAD SOFTWARE a complete digital engineering solution.

Empowering Modern Engineering with Integrated, Intelligent, and Automated Design Technology

Mechanical Computer-Aided Design (MCAD)

SIEMENS NX SOFTWARE delivers a flexible and high-performance MCAD environment tailored for modern product engineering. Its synchronous technology combines the best of parametric and direct modeling, allowing designers to work faster and with greater design freedom.

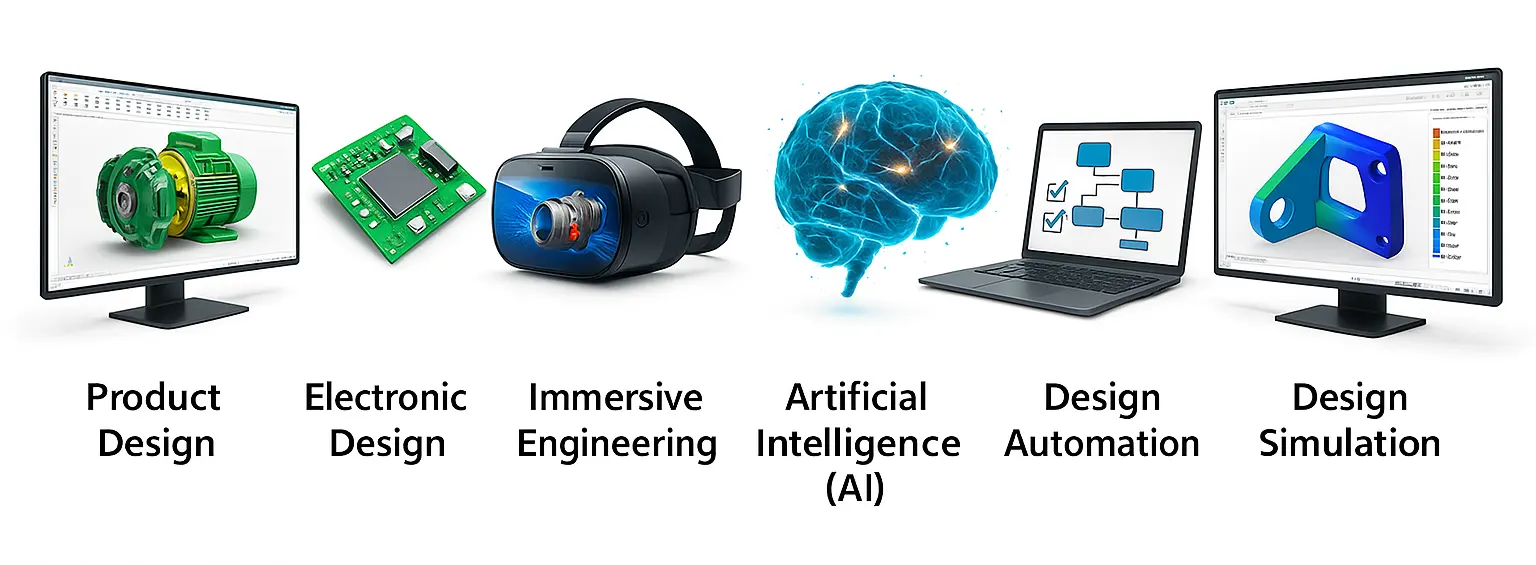

Product Design

SIEMENS NX provides intuitive and robust tools for the entire product design workflow—from concept sketches to detailed engineering models and large assemblies.

Key strengths include:

- Powerful solid, surface, and hybrid modeling

- Feature-based, history-free, or hybrid modeling approaches

- High-performance assembly design for thousands of components

- Fully associative drafting and automated drawing generation

Product Design

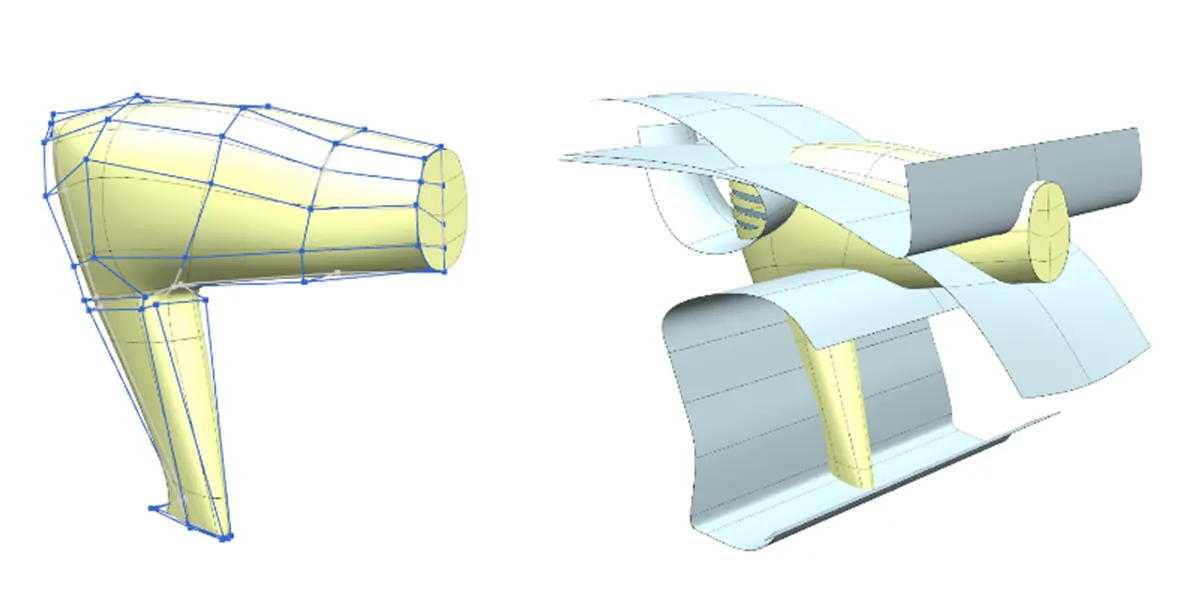

Industrial Design & Styling

NX supports high-end industrial design with specialized tools for elegant surfaces and product aesthetics.

Capabilities include:

- Class A surface creation with smoothness control s

- Real-time surface diagnostics and curvature analysis

- Rapid concept modeling and freeform sculpting

- Photorealistic visualization using NX Render

These tools help designers create visually appealing, ergonomically refined products with precision.

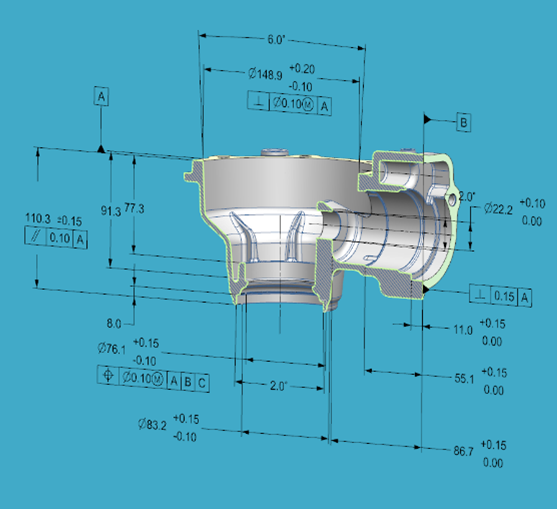

Model-Based Definition (MBD)

NX enables a drawing-less, fully digital approach to manufacturing documentation. All product information—dimensions, tolerances, GD&T, notes—is embedded directly into the 3D model.

Benefits:

- Eliminates 2D drawing dependency

- Ensures a seamless digital thread across manufacturing, inspection, and quality

- Reduces errors and improves data consistency

MBD is a foundational element for modern digital manufacturing.

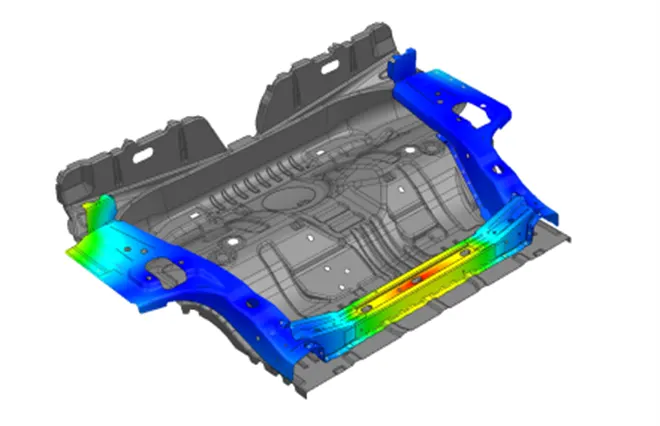

CAD-Integrated Simulation

NX tightly integrates CAD and CAE, enabling simulation-driven design inside the modeling environment.

Engineers can perform:

- Structural and thermal analysis

- Motion studies and mechanism validation

- Vibration, flow, and fatigue checks

- Associative simulations that update with design changes

This reduces costly late-stage rework and promotes validated designs early in the lifecycle.

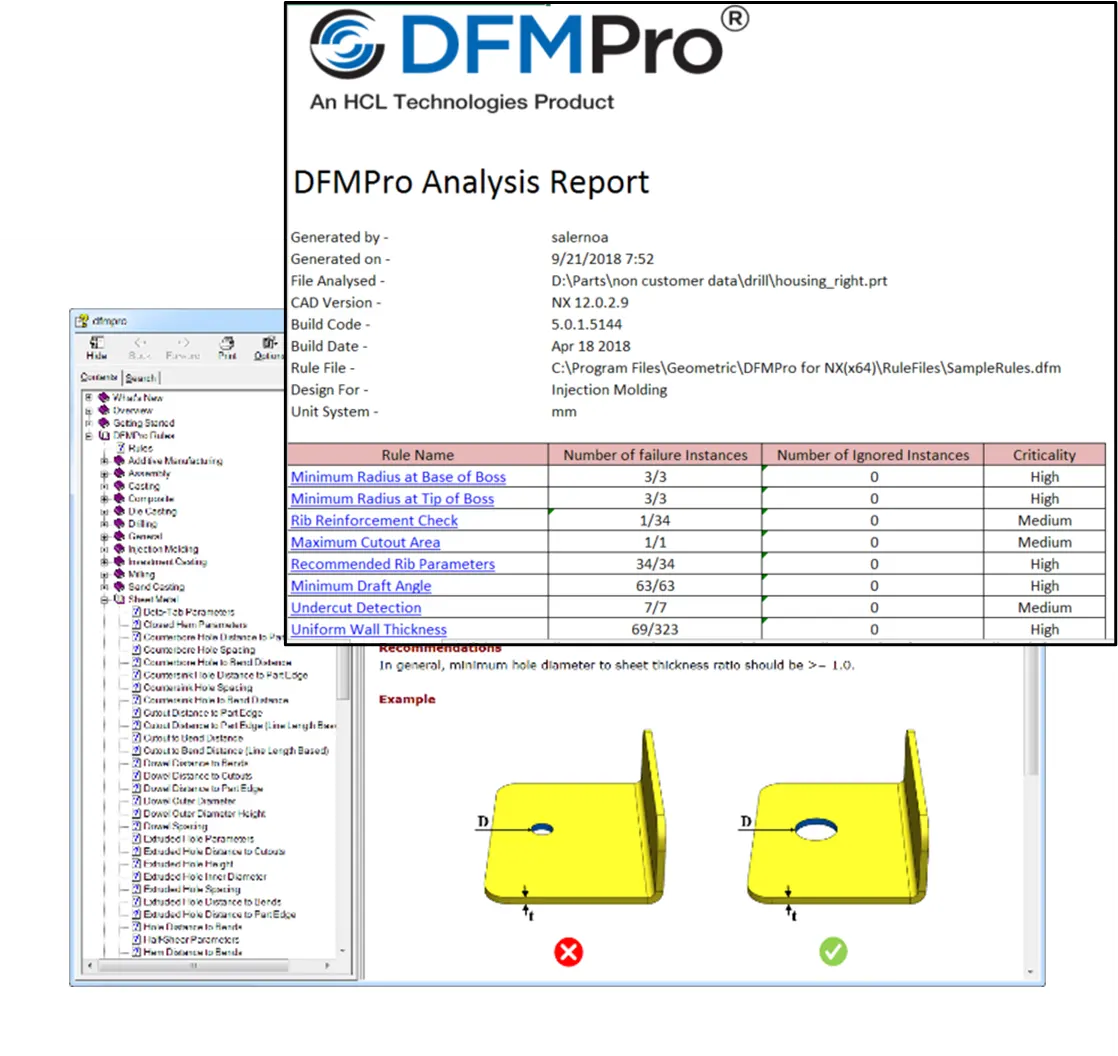

Design Validation

NX includes intelligent tools to verify design quality before moving into manufacturing.

Validation tools cover:

- Interference and clearance checking

- Wall thickness and draft analysis

- Assembly motion evaluation

- Manufacturability checks for machining, sheet metal, mold design

These tools help avoid design flaws and improve product robustness.

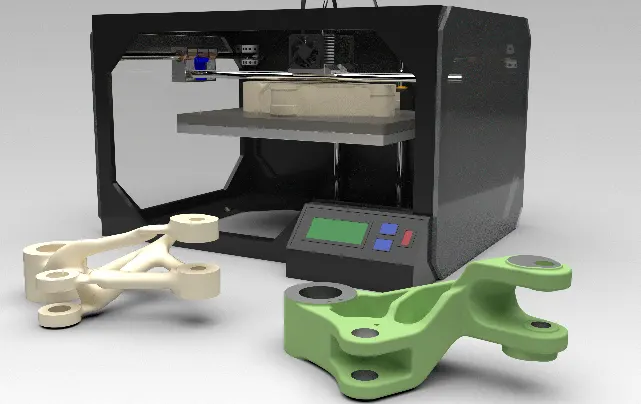

Design for Additive Manufacturing (DfAM)

With built-in additive design functions, NX enables engineers to create optimized, lightweight, and production-ready parts.

Features include:

- Topology optimization

- Lattice structures and lightweighting tools

- Build orientation, support generation, and tray setup

- Predictive simulation for additive processes

NX provides a complete path from concept to print-ready output.

Mechanical Routing Design

NX simplifies the design of mechanical routing systems such as hoses, tubes, and pipes.

Capabilities:

- Automated routing based on rules and specifications

- Standard libraries of elbows, tees, valves, and fittings

- Accurate length calculations and BOM creation

- Integration with manufacturing workflows

This is essential for machinery, process equipment, HVAC systems, and heavy engineering.

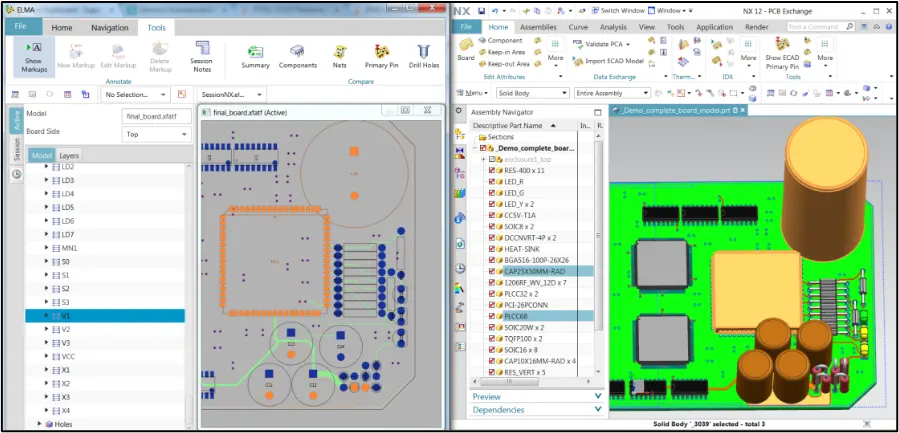

Electronic and Electrical Computer-Aided Design (ECAD)

SIEMENS NX CAD bridges the gap between electronics and mechanical engineering by supporting seamless ECAD–MCAD collaboration.

Key capabilities:

- Real-time co-design between PCB and mechanical engineers

- Automatic clearance, packaging, and thermal validation

- Harness and wiring design with associative routing

- Integration with Siemens electrical design tools (Capital, Xpedition)

This ensures design accuracy, reduces integration issues, and accelerates electromechanical product development.

Immersive Engineering

NX supports VR/AR-based immersive visualization, enabling engineers to interact with their digital prototypes in full scale.

With immersive engineering, teams can:

- Walk around large assemblies in virtual reality

- Conduct ergonomic studies and assembly reviews

- Identify design issues that are hard to detect on 2D displays

- Collaborate with remote stakeholders in a shared virtual environment

This improves decision-making and design understanding across the product lifecycle.

Artificial Intelligence (AI)

CJ TECH PVT. LTD – has been a trusted advisor for the manufacturing industry, and have been successfully addressing NX CAD SOFTWARE REQUIREMENTS for the last fifteen years.

AI is deeply integrated into NX, making it more intuitive, predictive, and adaptable.

AI enhances engineering productivity through:

- Intelligent command prediction

- Automated feature recommendations

- Behavior learning from user patterns

- Proactive detection of design issues

This transforms NX into an intelligent engineering assistant that reduces repetitive work and speeds up design cycles.

SIEMENS SOFTWARE NX incorporates advanced AI-driven capabilities for:

- Automatic geometry classification and feature recognition

- Topology and shape optimization for lightweight designs

- Automated design generation based on constraints

- Real-time quality checks and manufacturability prediction

AI helps engineers explore better design possibilities with less manual effort.

Design Automation

One of the most powerful capabilities of SIEMENS NX is Design Automation, enabling organizations to convert engineering knowledge into rule-based, configurable templates.

Using tools like Product Template Studio (PTS), Knowledge Fusion, and parametric modeling, companies can automate repetitive tasks and create instant design variants.

Automation capabilities include:

- Rule-driven geometry creation

- Configurable product templates for rapid variant generation

- Automated drafting, BOM creation, and report generation

- User inputs based on forms or spreadsheets

- Integration with PLM and ERP systems

Frequently Asked Questions

NX CAD is a comprehensive computer-aided design software developed by SIEMENS PLM Software. It offers powerful tools for product design, engineering, and manufacturing.

Key features include advanced 3D modeling, assembly design, drafting, simulation, and integrated CAM capabilities, among others.

Yes, NX CAD is optimized to handle large assemblies efficiently, allowing designers and engineers to work on complex projects without sacrificing performance.

NX CAD supports various file formats for seamless collaboration with other CAD software, ensuring interoperability across different platforms.

Yes, NX CAD provides cloud-based collaboration features, enabling teams to work together in real-time from anywhere with an internet connection.

Yes, NX CAD includes CAE capabilities for performing finite element analysis, allowing engineers to simulate and validate product designs for structural integrity and performance.

Yes, SIEMENS PLM Software offers training programs and resources for NX CAD users to enhance their skills and productivity.

NX CAD is widely used across industries such as automotive, aerospace, machinery, consumer products, and electronics for product design and development.

Yes, NX CAD supports parametric modeling, enabling users to create design features that can be easily modified and updated throughout the design process.

Yes, NX CAD includes drafting tools for generating detailed manufacturing drawings with annotations, dimensions, and other necessary information.