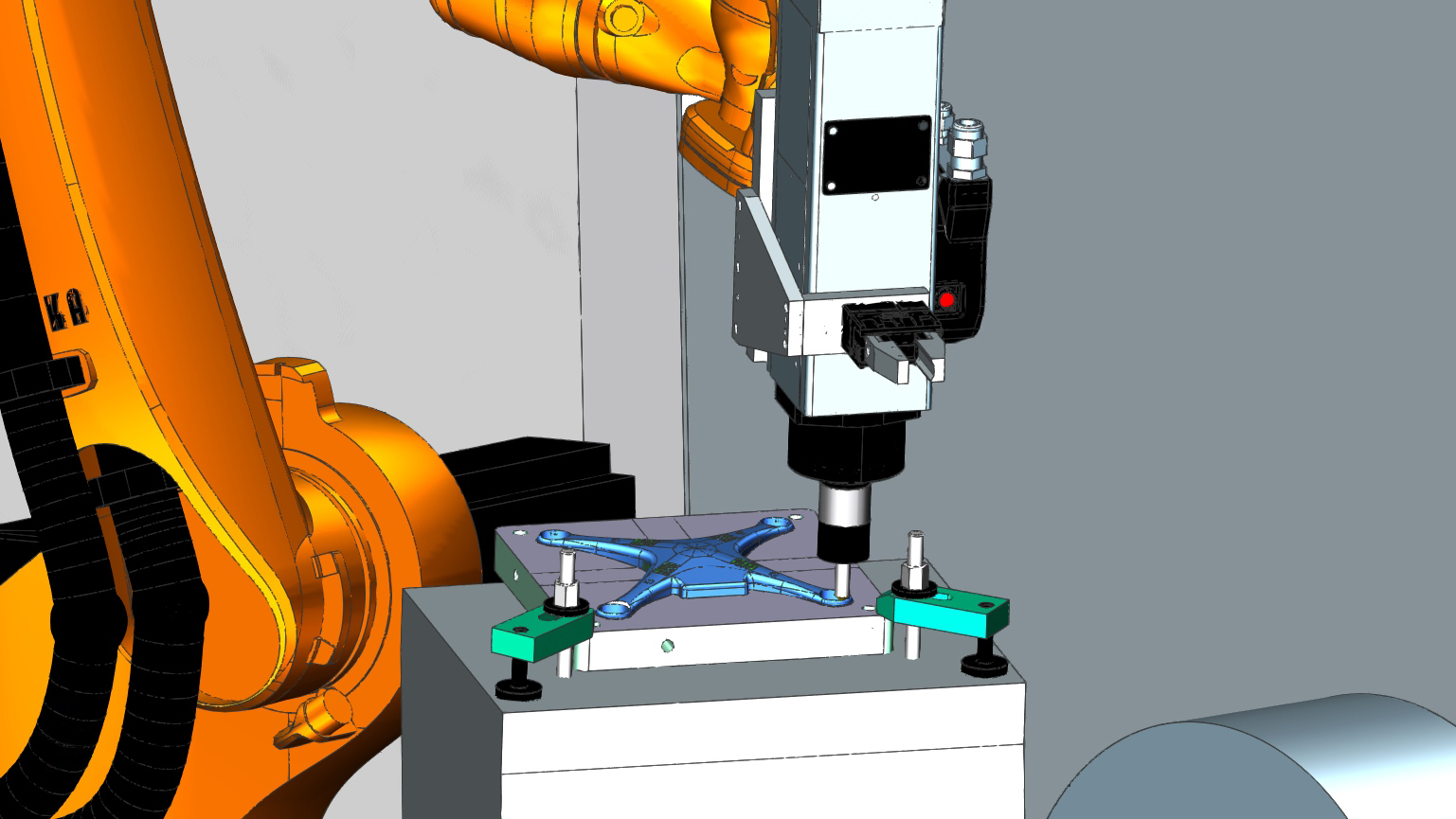

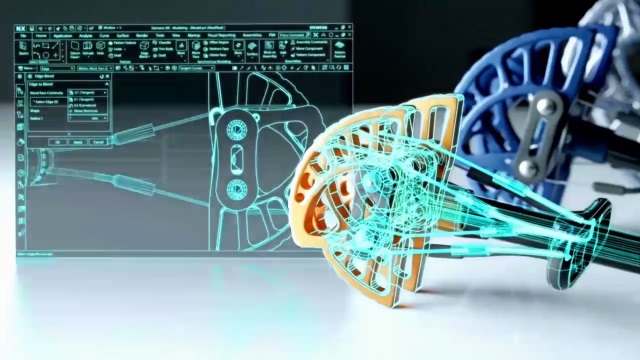

CAM in modern manufacturing processes is a critical element. It connects design with production.

Solid Edge CAM provides for CNC (Computer Numerical Control) machining, a comprehensive collection of easy-to-use solutions. They help manufacturers achieve in their operations greater efficiency with precision.