When it comes to manufacturing big machines and units like planes and cars, it is important to carefully design the product to leave no space for flaws. It is true that car design just doesn’t pop up in the minds of engineers and comes into existence, but there goes a lot into making it. Designing and prototyping require resources, creating more manufacturing waste, which is also unsustainable. Thanks to Simulation software that helps businesses get into the details of the design virtually instead of physically prototyping. This saves cost and time and is indeed more sustainable.

One such very popular software is Siemens simulation software, known as Simcenter. Simcenter engineers help develop sustainable products using predictive simulation and test applications. This process combines advanced engineering tools with industry expertise and dedicated support to create innovators.

How Does Simcenter 3D Work?

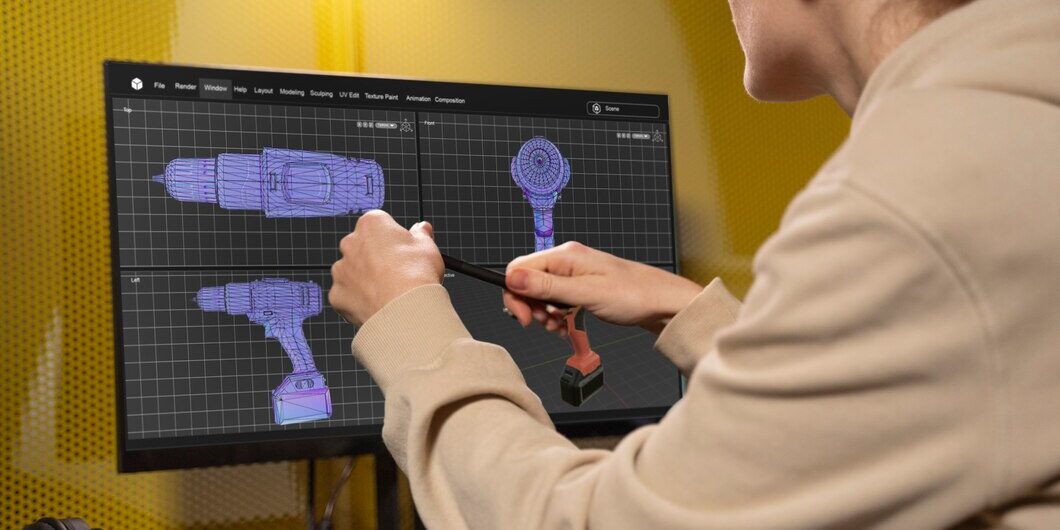

Simcenter 3D is a revolutionary name in the simulation industry. It aids you in modeling and evaluating complex details of a product and its performance. It integrates collective domains of physics to form a single simulation environment, making you reach the depth of your product and design faster.

Features That Make Simcenter 3D A Great Choice

Simcenter 3D is a complete CAE pre- and post-processing environment that includes sophisticated capabilities for geometry manipulation. These capabilities help abstract and defeature CAD geometry from any original source.

It accelerates the modeling process and aligns the model with the most recent design. Simcenter 3D also enables a myriad of simulation applications and provides the special capability to associate analysis models with design data, which assists engineers in maneuvering the process in a progressive direction.

Want more reasons?

You can now simulate the intricate structure

The innovation process is indeed intricate. But now, you can anticipate behavior, improve accuracy, and have faith in preliminary designs. You can use performance-based systems engineering to monitor the complete product lifetime, from component concept to ultimate operational use.

You can now work as a consolidated team

Using simulation software helps you share your ideas and collaborate as a consolidated team. Thus, you can now organize teams and connect all processes in even the most complicated development environments. With an integrated digital thread that links product data to simulation models, it makes it easy to balance performance and guarantees traceability.

You can now assess and evaluate alternatives

Simulation software allows you to utilize intricate models to investigate the design space thoroughly. Prior to committing to the final design, you can use your saved time to obtain an understanding of the digital environment. This can help you find novel designs, increase robustness more quickly, and optimize performance.

You own the speed; therefore, Accelerate!

Avoid the hassle of creating concrete models and leverage the digital platform for faster production and market reach. With engineering powered by artificial intelligence (AI), you can also swiftly shift client preferences. With Simcenter, you get the space to utilize the newest automated workflows along with scalable, cloud-based procedures.

Test Solutions And Simulations

To guarantee that your product performs exactly and better than how you have perceived, engineering needs precise forecasting of the product performance. With Simcenter solutions, your engineering teams can push the boundaries, tackle the most difficult problems, and get innovations to market more quickly. Providing the ultimate solution, Simcenter lets you transform product intricacies into a competitive advantage. Its simulation features are flexible and accommodate almost every type of product.

Types Of Simulation Of Simcenter

Simcenter fluid and thermal simulation

CFD and computational chemistry software enable faster product innovation by simulating fluids and thermal simulations. Engineers can model complexity, make critical decisions, explore possibilities, and design novel materials.

Simcenter electromagnetics simulation

Electromagnetic simulation enhances efficiency, compatibility, and performance in complex electromagnetic environments. It uses dedicated solvers for transformative CAE processes, ranging from fast initial analysis to inherent realism for final verification.

Simcenter physical testing

This solution emphasizes the importance of testing faster, smarter, and earlier in development. It focuses on the use of digital twins for performance validation, frontload testing for critical insight, streamlined testing campaigns, and smarter testing for team collaboration.

Simcenter systems simulation

This simulation enables the creation of diverse system architectures, extending the digital twin concept to software engineering. It helps engineers address complex smart, automated, and electrified products and share models with global engineering teams.

Simcenter Mechanical simulation

Using mechanical simulation tools, you can predict mechanical performance across multiple physics domains, reduce reliance on physical prototypes, speed up the simulation process, accurately simulate industry-leading solvers, and streamline complex multiphysics analyses.

Simcenter autonomy solutions

This solution aims to streamline productive journeys in the future of mobility. It works by incorporating driver assistance systems, level 5 and total autonomy, and testing designs in mixed environments.

Simcenter simulation process and data management

In the digital transformation era, consider using a simulation process and data management (SPDM) system instead of managing simulation data in silos or shared file systems for increased productivity.

Model-based system engineering

Use industry-leading co-simulation and model-based systems engineering to assure system performance versus requirements. You can also expedite product development and offer early concept design insights using MBSE solutions.

Conclusion

Siemens promises efficacy in every step of the product lifecycle through its comprehensively designed software and solutions. Keeping in mind the needs of the corporate world and changing trends, you can easily integrate PLM, CAD, and CAE-based processing in a sustainable manner.

Helping brands forge a trailblazing path ahead in the field of technology through simulation software, CJ Tech has devised the best solution for your specific needs. Join hands with CjTech and enjoy a reliable software service.