Injection molding plays a critical role. It’s extensively used in manufacturing process to produce plastic parts. What has made it a preferred choice for industries from automotive to packaging is it facilitates high-speed production with high precision and low material waste. However this cannot be achieved without mastery injection molding. It’s essential to have mastery over the mold design process.

That’s where Siemens NX plays a key role.

Its comprehensive suite of tools with advanced capabilities makes it effective to design injection molds. Good mold design helps to minimize material waste; prevent defects like warping, air pockets, or sink marks; reduce cycle times; and above all, ensure dimensional accuracy and part quality.

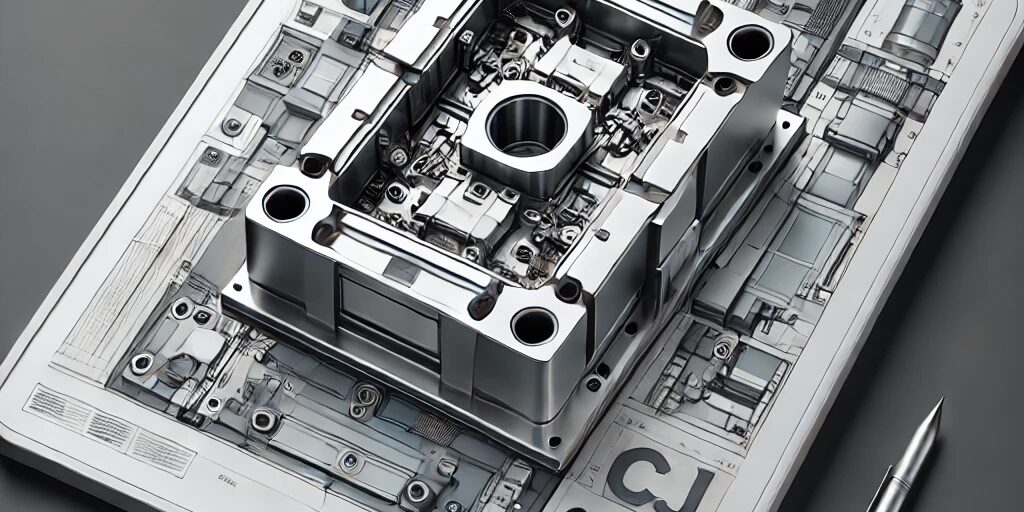

SIEMENS NX MOLD DESIGN

Siemens NX is a proven CAD/CAM/CAE software solutions provider. Its suite of products have revolutionized across industries design, analysis, and manufacturing processes. NX Mold Design in the realm of injection molding offers a powerful set of tools. These tools enable designers and engineers to optimize each and every phase of mold design. That is, from conceptualization to production.

The following tell why NX Mold Design for injection molding design.

ADVANCED MOLD DESIGN CAPABILITIES

NX Mold Design is a specialized module for mold design. It offers a set of tools with features for parting line design, core cavity creation, ejector pin design, cooling channel layout, and runner systems. They make for a standard choice for injection molding applications.

NX Mold Design software

- Enables seamless integration between design, analysis, and manufacturing. Users will be able to work with the latest and accurate data.Allows designers to focus on precision and performance.

- At the same time, automate time-consuming tasks. Designers can quickly generate complex 3D models of molds that otherwise when designed manually would take much longer time.

3D modeling tools integration into the injection molding design process ensures every mold is created with optimal accuracy and efficiency.

NX MOLD WIZARD

A powerful Siemens NX feature, it automates and simplifies the mold design process. NX Mold Wizard

- Reduces to a significant extent the time needed to create a mold. It does this by automating many of the design steps. Like for instance, creating cavity geometries, parting lines, and core and cavity splits.

- Reduces errors and improve overall performance Users can easily define by following the software’s step-by-step process the molding process and modify in real-time the mold design parameters.

- Adapt quickly to changes in the design. With no compromise on quality, tight deadlines can be met.

SIMULATION AND OPTIMIZATION TOOLS

Siemens NX has advanced simulation capabilities. They have proven to be highly successful in designing for injection molding molds. It

- Offers tools that simulate the injection molding process. Users can anticipate potential issues before the mold is physically produced. NX Mold Flow analysis for instance helps to evaluate how plastic will flow through the mold. They allow designers to optimize the layout of the cooling channels, gating systems, and vents. In turn, they reduce chances of defects like warping or sink marks, or short shots.

- Provides structural analysis tools. They help to assess mold’s strength and durability under high pressures and temperatures. This ensures it can withstand the injection molding process’s stresses.

Designers using these simulation capabilities can refine their designs. They can also optimize its performance and reduce during production the risk of expensive mistakes.

SEAMLESS COLLABORATION AND DATA MANAGEMENT

Injection molding design requires among teams seamless collaboration. It is a prerequisite to delivering on time quality products. Siemens NX provides robust collaboration tools. Stakeholders from manufacturers, to engineers, and designers can in real-time work on the same project.

It’s Teamcenter Integration

- Enhances collaboration by offering centralized repository for design data. They help teams to stay aligned with and maintain track of design changes.

- Ensures harmonious communication flow and data management. They reduce the risk of miscommunication and at the same time, improve overall workflow efficiency.

AUTOMATION AND CUSTOMIZATION

Automation in Siemens NX streamlines for injection molding mold design. The software for instance allows users to create custom templates and standard libraries for mold components. They significantly speed up the design process.

These libraries and templates also

- Ensure all molds are designed with consistency in line with industry standards.

- Allow custom automation tools to be tailored to meet specific company needs. They ensure the unique processes and design methodologies are throughout the mold creation process followed.

- Allow the integration of other tools. The entire design and manufacturing ecosystem get to seamlessly works together.

MASTERING INJECTION MOLDING DESIGN

The following tell key aspects of mastering injection molding in NX.

HOW TO MAKE MOLD IN NX?

Making in Siemens a mold is a structured process.

Designers

- Create a 3D model of the part to be molded. After the part is designed, NX’s suite of tools is used to define the core and cavity and also the parting line. Following this, NX Mold Wizard is used to automatically generate these features in line with the part geometry.

- Define the mold structure. This includes the mold base, ejector pins, cooling channels, and gating system. Using NX software, highly detailed molds is created with realistic simulations of material flow and thermal behavior.

- Export the design once the mold design is completed. The design is exported to CAM software for toolpath generation and CNC machining.

MOLD DESIGN SOFTWARE BENEFITS

The following outlines Siemens NX Mold Design Software benefits.

SPEED WITH EFFICIENCY: Designers using tools like Mold Wizard, Automation, and Built-in-Templates, can significantly speed up the mold design process.

ACCURACY WITH PRECISION: Integration of advanced simulation tools ensures molds are designed with high precision. This reduces defects in the final product.

FLEXIBILITY: Powerful customization options allows the software to be tailored to unique requirements.

COLLABORATION: Real-time collaboration features with data management tools help streamline communication. They in turn ensure a smoother design-to-production process.

CJ TECH’S ROLE IN INJECTION MOLDING DESIGN

Leading product design and engineering services provider, CJ Tech plays a critical role. It enhances through Siemens NX injection molding design. CJ Tech specializes in helping organizations to optimize their design and manufacturing processes. This ensures their injection molds are efficient and cost-effective.

It has

- Proven expertise in NX Mold Design. It is well-positioned to offer to clients across industries results-driven solutions. The CJ Tech team is well-versed with different layers of NX Mold Wizard Processes. This ensures each mold design is tailored to meet specific project needs and at the same time, help reduce development costs and time.

- Extensive experience across industries in simulation and optimization. The CJ Team ensures molds are designed to deliver maximum performance. By leveraging Siemens NX’s advanced capabilities, they also offer critical insights into every aspect of the injection molding process. That is from part design to mold creation and manufacturing.

CONCLUSION

Manufacturers always look to streamline their design processes. They also seek to improve product quality. That’s where; Siemens NX’s advanced capabilities help. It offers everything that is required to mastering injection molding. Be it creating simple as well as complex molds. They help to reduce costs and at the same time, accelerate time-to-market.

Leading design solutions software provider, CJ Tech with its proven capabilities in Siemens NX can leverage it for injection molding designs. Its expertise in NX Mold Design will ensure injection molding designs meet the highest quality and performance standards.

FAQs

1. How Is Siemens NX related to injection molding?

- A comprehensive software suite, Siemens NX integrates NX CAD, CAM, and CAE capabilities. It is extensively used to create and optimize mold designs in injection molding design. Using it engineers can streamline the whole mold design process. That is, from concept to manufacturing, and improving efficiency and accuracy in production.

2. How is Siemens NX suitable for mold design?

Siemens NX provides a powerful set of tools. They

- Offer all-round mold design capabilities. This includes, the NX Mold Wizard which automates vital tasks. Tasks like parting line definition, draft analysis, and core/cavity extraction.

- Simplify the process of mastering injection molding.

- Enhance productivity and reduce design time. At the same time, ensure molds are optimized for performance.

3. What’s NX Mold Wizard? How does it assist in injection molding design?

The NX Mold Wizard is an integral part of Siemens NX. It

- Provides easy-to-use templates for NX mold design.

- Guides users through the mold creation process. They help with the definition of mold bases, insert features, cooling channels, and ejection systems.

- Speeds up the design phase significantly. This ensures consistent, high-quality results.

4. Compared to other mold design software, what benefits does Siemens NX Mold Design offer?

- NX Mold Design synergizes advanced functionality with automation. With features like automated design validation and optimized cooling strategies, Siemens NX Mold Design,

- Enables manufacturers to swiftly generate that mold designs are highly efficient and cost-effective.

- Reduces manual errors and accelerates design-to manufacturing timeline.

- Offers a significant edge over competing software solutions, with its seamless integration with CAD and CAE tools.

5. How to make a mold in NX?

- Siemens NX offers extensive documentation, tutorials, and training materials. They guide users on how to make mold in NX.

6. What is CJ Tech role in injection molding design?

- CJ Tech plays a critical role. It supports manufacturers using Siemens NX for injection molding design.

- Provides tailored solutions that help organizations. They help to maximize the potential of NX software in optimizing their mold designs, improve operational efficiency, and achieve faster-to-market products’.

- Provides expert consulting and training.

7. How can mold design processes be improved with Siemens NX?

- Siemens NX provides for mold design processes comprehensive array of tools. From part analysis to mold flow simulation.

- Integration of advanced features like automated draft analysis, core and cavity creation, and tooling design,

- Facilitates faster and more accurate mold designs.

- Assists engineers visualize how the mold will perform before manufacturing starts. This reduces the need for expensive physical prototypes.

8. Can I use Siemens NX mold design software for small and large-scale injection molding projects?

- Yes. Being scalable, it can adapt to a wide array of injection molding projects. Siemens NX, be it designing small intricate parts or large, complex molds, offers required tools with capabilities. They help to efficiently handle projects of all sizes’.

9. Why should I for my business choose Siemens NX Mold Design Software?

It is just perfect for companies like yours to streamline injection molding design processes. It

- Enables by integrating automation with advanced design validation and simulation, faster development cycles and improved mold performance.

- Facilitates seamless collaboration across teams and departments.

- Helps reduce manufacturing costs.