PDM Software Solutions

Product data management or product life cycle management as it is also referred to is a system that controls and manages all information regarding the particular product throughout the life of the product. They have the advantage of consolidating data, controlling the version of documents, and avoiding repetitions in the organization’s processes so that all interested parties have updated and reliable information available. In the manufacturing lifecycle, PDM software solutions have a significant part to play as a communication channel, co-ordinator, and quality controller of product and process information across design, manufacture, and documentation.

When the implementation of PDM software solutions is not applied, firms are likely to experience problems including duplicating data, frequent data errors, poor flow of work, and communication issues, all of which result in costly work needed to correct problems and schedule congestion. These problems are resolved by the application of PDM, as this approach is described as more structured and integrated in comparison to the traditional methods.

PDM SOFTWARE SOLUTIONS FOR THE MANUFACTURING INDUSTRY

Organizations today handle more data than ever and also deal with more data points than ever. Managing complex data efficiently in such a scenario can be extremely challenging. That’s where PDM Software plays a critical role.

PDM (Product Data Management) software is designed to

- Centralize, handle, and manage all product-related data. This includes bill of materials (BDM), design files, documents, technical specifications, and other critical product-related information.

- Ensure a single point of genuine data for product details. This helps to streamline operations and improve collaboration among teams.

- Provide a higher degree of structure and control with automation. This ensures all teams members can access at all stages of the product lifecycle, precise and latest product information.

An investment in Product Data Management (PDM) is not just an investment. It’s an investment to drive excellence in every aspect of your product development cycle. We at CJ Tech are committed to ensure your investment in PDM is truly worth it. We help you harness the capabilities of PDM to its fullest to drive efficiency and success. With CJ Tech as your partner, you get implementation support with tailored training programs, and expert advice to navigate the PDM landscape,

PDM Software KEY FEATURES

CENTRALIZED DATA REPOSITORY

- Stores all product data in a single, secure location.

- Eliminates the need for across departments and systems, scattered data.

VERSION CONTROL AND REVISION MANAGEMENT

- Maintains a history of all alterations effected to product data. This includes design files and specifications.

- Ensures teams get to work with the latest version. This prevents errors arising from outdated information.

- Allows manufacturers track product’s evolution. From inception through to final production.

BILL OF MATERIALS (BOM) MANAGEMENT

- Drives efficient BOM management. All materials and components needed for manufacturing are tracked accurately.

- Facilitates creation of accurate cost estimates and resource planning.

COLLABORATION TOOLS

- Drives seamless collaboration. Across teams, locations, and even time zones.

- Ensures real-time updates and notifications. Alterations to product data get communicated quickly. This reduces errors. And improves productivity.

ACCESS CONTROL AND SECURITY

- Offers granular control. This ensures control over who can access and modify different types of data. They help maintain product designs’ integrity.

- Ensures only authorized individuals can effect changes to vital information.

WORKFLOW AUTOMATION

- Provides workflow automation tools. They help streamline business processes. Like design approvals, change requests, and document management.

- Saves on time. Manufacturers can focus on more strategic activities.

INTEGRATION WITH OTHER SYSTEMS

- Integrates with other enterprise software systems seamlessly. Like CAD tools, ERP systems, and CRM platforms.

- Ensures across the organization smooth data flow. They help drive more efficient decision-making.

Core Functionalities of PDM Software

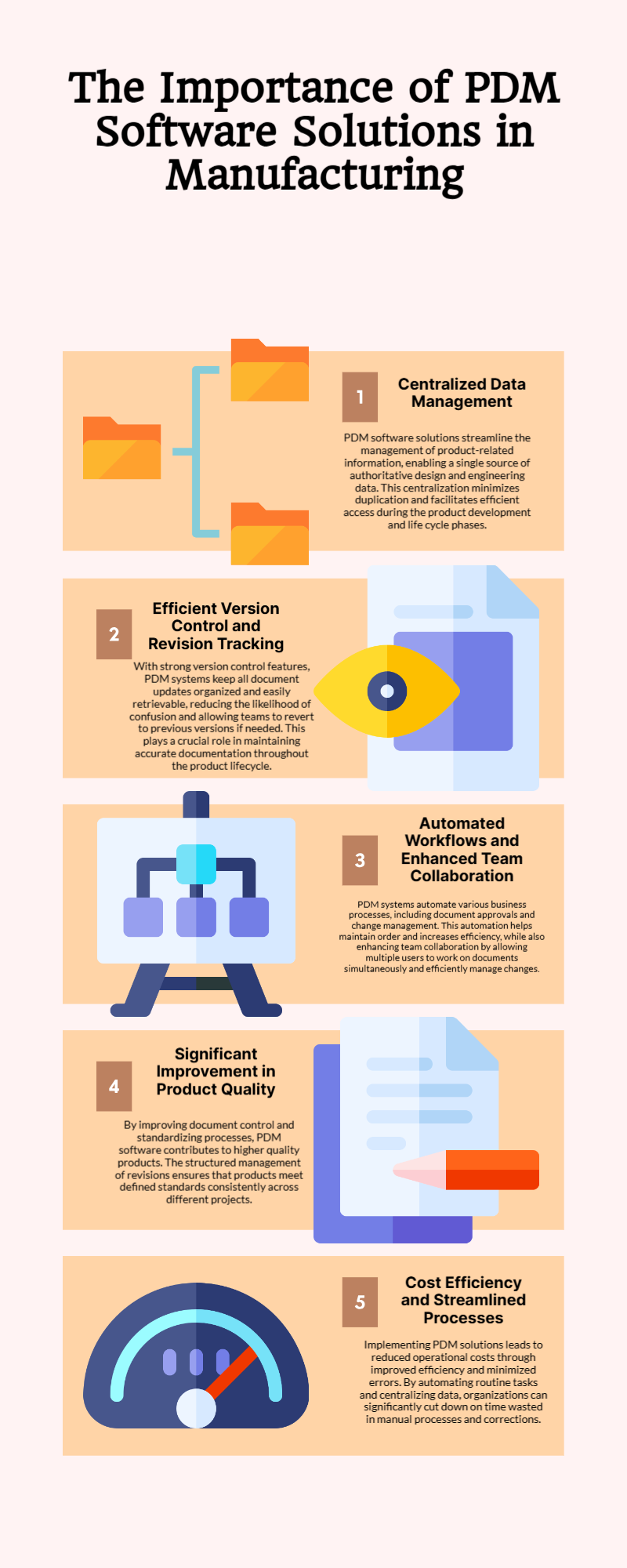

Data Management and Organization:

Product Data Management (PDM) systems improve the management of product-based information throughout the PDCA cycle by directing the collection, organization, and access. They establish a single authoritative source of design and engineering information, simplicity. PDM Software systems also aid in data categorization and arrangement to allow for orderly working through files and in the storage of data.

Version Control and Revision Management:

The Product data management systems also offer a strong consideration of version control and revision management. They monitor files containing document and design content and keep versions and updates for that information stored and easily retrievable. This functionality is useful to prevent confusion and mistakes that can be introduced by others accessing the same document and allowing one to revert to a prior version, if necessary.

Workflow Automation and Approval Processes:

WFA about Product data management systems defines, manages, and optimizes business processes within organizations including authorizations of documents, change management, among others, and task delegation. Automation means that activities happen in pre-designed sequences hence helping to maintain order instead of constant interferences. This automation assists in maintaining a standard in the approval procedure of a project and helps in the timely continuation of the same.

Collaboration and Team Management:

PDM systems enable enhancement of the interaction of a team working on a particular project in the sense that the tool offers a share of documents, manages the changes made, and offers a forum for conversations. They also support working on documents in parallel to the extent that many users can make updates to the same as well as share data at the same time and resolution of conflicts and version control is achievable.

Document and Drawing Management:

Product data management systems effectively organize documents and drawings because they offer solutions for making, archiving, and searching for documents stored in various formats. They /endorse versioning, indexing, and linking of the document to projects or parts of them, so that any related data is easily retrievable and current.

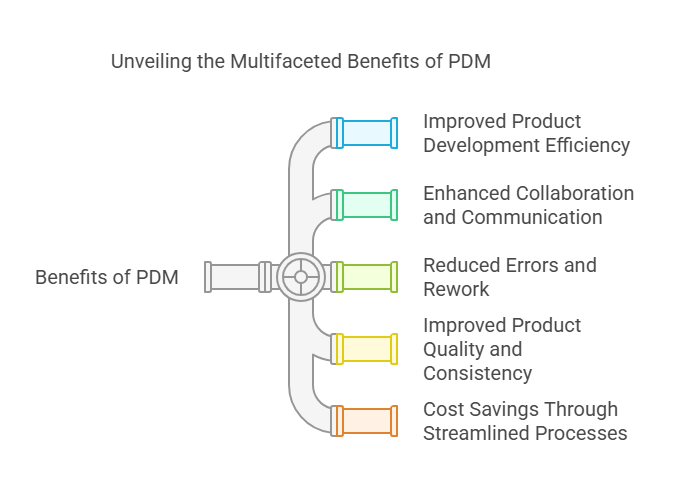

Benefits of Implementing PDM

Improved Product Development Efficiency:

The utilization of PDM systems greatly improves the speed and productivity of product development as it decreases the time spent on repetitive activities and task routing. Centralization of data means that there is less amount of time needed to find the data, automation of approval and revisions and other time-consuming processes contributes to a faster completion of the project.

Enhanced Collaboration and Communication:

PDM systems enhance teamwork since they create a central point where individuals in a team can access documents, versions, amendments, iterates, etc. This integration helps in making all the stakeholders to be at par with one another to avoid cases of misunderstanding thereby enhancing unity of work direction across the development stages.

Reduced Errors and Rework:

Through effective version control and revision management issues of error and those that would have required one to go back to previous phases are kept to a minimum. PDM also ensures that there is only one source of information because accurate tracking of change minimizes conflicts and thus boosts accuracy with the fewest number of errors.

Improved Product Quality and Consistency:

PDM systems help in the achievement of the organizational goal of standardization of design across different projects. Through the arrangement and control of documents and their revisions, PDM improves the products’ quality, and this implies that the various versions developed are good and standard as per the stipulated norms.

Cost Savings Through Streamlined Processes:

Such advances result in a drastic decrease in costs associated with the manual handling of different processes. PDM systems enable organizations to achieve greater levels of efficiency, lessen the likelihood of errors, and enhance cost control to enhance financial performance.

PDM software consolidates the information of products, optimizes the processes, and adds value for makers. Thus, PDM controls revisions to ensure it delivers success by allowing collaboration and increasing the quality of the products being developed. Here at CJ Tech, we have different PDM solutions depending on the necessities of the companies. Shall we change the product development process together? Contact us today!

FAQ

1. What is Product Data Management (PDM) in manufacturing?

PDM is a system that manages and controls product-related data throughout its lifecycle. In manufacturing, PDM centralizes information such as CAD models, bills of materials (BOMs), and documentation, ensuring that all stakeholders have access to the latest data. This centralization enhances collaboration and reduces errors

2. How does PDM software benefit manufacturing processes?

PDM software offers several advantages:

- Centralized Data Storage: Provides a secure repository for all product information.

- Version Control: Manages revisions to prevent inconsistencies.

- Improved Collaboration: Facilitates data sharing among teams, enhancing communication.

- Process Automation: Automates workflows like engineering change orders and approvals.

- Integration Capabilities: Connects with other systems such as ERP and CRM for seamless data flow.

These benefits lead to increased efficiency and reduced time-to-market.

3. Can PDM software integrate with existing systems in a manufacturing setup?

Yes, modern PDM solutions are designed to integrate with various enterprise systems, including Enterprise Resource Planning (ERP), Supply Chain Management (SCM), Customer Relationship Management (CRM), and Product Lifecycle Management (PLM) systems. This integration ensures a cohesive environment for product data and streamlines operations across departments.

4. How does PDM software enhance product quality and reduce errors?

By providing a single source of truth for all product data, PDM software minimizes discrepancies and ensures that teams work with the most current information. Automated workflows and approval processes reduce manual intervention, decreasing the likelihood of errors and enhancing overall product quality.

5. Is PDM software scalable for growing manufacturing businesses?

Yes, PDM solutions are scalable and can be tailored to meet the evolving needs of growing manufacturing businesses. As operations expand, PDM systems can accommodate increased data volumes, additional users, and more complex processes, ensuring continued efficiency and data management.

6. What security measures are in place within PDM software?

PDM software includes robust security features such as user authentication, role-based access control, and audit trails. These measures ensure that only authorized personnel can access or modify sensitive product data, maintaining data integrity and compliance with industry standards.