In the fall and flight of technical advancements users who seek more scalable yet easy solutions for engineering challenges, Solid edge is just the perfect answer. Siemens Solid Edge portfolio offers affordable, user-friendly software tools for product development. This includes direct modeling speed and simplicity with parametric design flexibility and control which is enabled by synchronous technology.

But what exactly is Solid Edge CAD?

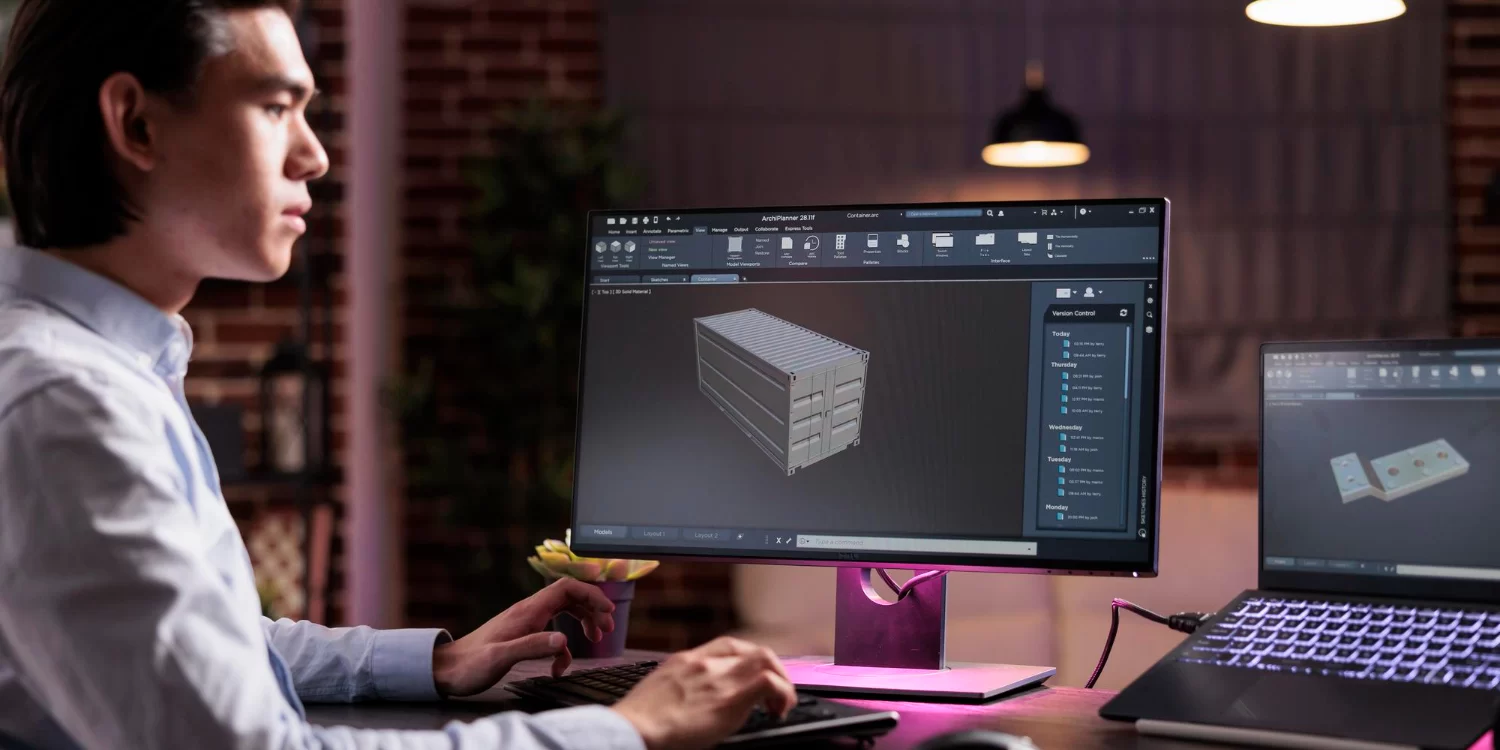

Solid Edge is a 3D computer-aided design (CAD) programme developed by Siemens Digital Industries Software. The primary function of solid edge CAD software is to solve complex engineering problems for mechanical designers. It can be integrated with PLM systems such as Teamcenter as it provides solid modelling, assembly modelling, and 2D orthographic view functionality for Microsoft Windows.

Solid edge and mainstream mechanical designing.

Solid Edge Design is the only mainstream mechanical system that facilitates cross-team collaboration and coordination of activities by integrating CAD tools with design management features. This approach guarantees creative, error-free designs and helps in getting rid of misunderstandings.

Solid Edge production employs cutting-edge technology to produce accurate and efficient results in a variety of production processes. From CNC machining, nesting, assembling, 3D printing to additive manufacturing everything gets furnished without errors.

Also Read: Manage The Lifecycle Of Any Product Using PLM Software

Features of Siemens Solid Edge

1. Cloud based collaboration and design

Solid Edge is a cloud-ready software for product design that offers easy access to professional 3D CAD across devices. Its instant configuration of CAD environments, and quick data sharing with colleagues, suppliers, and customers make it a comfortable approach for designers. It eliminates the need for IT support, allowing users to focus on productivity of projects instead of daily system maintenance.

Through Siemens’ Teamcenter Share, Solid Edge provides safe, cloud-based design and engineering project collaboration. Users can access their customised CAD environment from any device, update software as needed, and share files with ease.

2. 3D CAD designing

Solid Edge is a next-generation 3D designing tool that supports generative models, additive manufacturing, and reverse engineering. Its Synchronous Technology combines direct modeling with parametric design for speed and simplicity. It also supports sheet metal design, assembly modeling, and management.

With its Modular Plant Design feature you can effortlessly streamline P&ID workflows with database-driven access to pipe specifications. Moreover 3D CAD’s Cloud-Ready Design allows easy access across devices and quick data sharing while using artificial intelligence for Adaptive UI.

3. Electrical designing

Solid Edge software automated the electrical design-to-production process, which also generates a bill of materials, manufacturing reports, and fully scaled, production-ready drawings. Additionally, it makes the construction, routing, and arrangement of wires, cables, and bundles in mechanical assembly more efficient.

In addition, the software provides a process-driven environment for PCB design that includes hierarchical 2D/3D planning, sketch routing, and ECAD/MCAD collaboration. The programme also offers a collaborative environment that is open and interoperable for the creation of printed circuit boards.

4. Data management

Solid Edge provides manufacturing companies with scalable data management systems that provide prompt action to enhance the performance of product development. The solutions make it possible to quickly get accurate information, safeguard and manage product data, and collaborate with downstream operations.

When it comes to engineering changes and release to manufacturing, they adhere to industry best practices. Options include the extensive CAD data management and PLM capabilities of Teamcenter and the integrated data management capabilities of Solid Edge.

5. Simulation

Solid Edge provides a number of simulation features, including embedded computational fluid dynamics, finite element analysis, and digital validation of part and assembly designs. Engineers may digitally evaluate designs with its integrated Finite Element Analysis (FEA) tool, which eliminates the need for physical prototypes and shortens design time.

Simcenter FLOEFD for Solid Edge enhances product performance and reliability by integrating CAD environments with computational fluid dynamics (CFD) analysis. It allows quick, adaptable, and precise modeling of thermo-fluid systems, with Simcenter Flomaster for Solid Edge automatically building models from CAD data for 1D processing and visualization.

6. Technical Publications

Solid Edge integrated technical publications solutions allow users to work directly with their Solid Edge parts and assemblies without converting CAD files to a different format. This speeds up the engineering change process and ensures that published documents reflect the current design. Solid Edge Illustrations allows users to create detailed 3D PDF documents and cloud-ready illustrations from Solid Edge files and other 3D CAD formats.

Solid Edge 3D Publishing is an easy-to-use software that embeds Solid Edge and other 3D CAD models into documents, allowing for easy creation of training and work instructions, illustrated parts catalogs, service and support documentation, and product manuals. The integration with Siemens’ Teamcenter PLM software shortens the cycle between design and documentation, ensuring direct access to design data.

Also Read: Top 3 Teamcenter Features to Enhance Collaboration in Engineering Teams

What’s more convenient than an all in one software that covers the fundamentals of mainstream designing? If Siemens solid edge is the power software that you need, then join CJ Tech for a comprehensive understanding of the maintenance and designing process.