Tired of those slow-going processes and want to boost your manufacturing ability? Don’t worry! A NX Simulation tool can help you overcome your challenges by streamlining the entire product design process. Today the industrial competition is fierce, and so is the production process. If you want to stay one step ahead, you should try modern technologies to boost your productivity.

NX Simulation is essential to manufacturing solutions since it combines production, simulation, and design into one platform. There are various alternatives, the popular one being Siemens NX, which consists of NX CAD and NX CAM, which is designed to provide design, simulation, and manufacturing solutions that are efficient and accelerate product delivery. We at CJ Tech can be your reliable technology partner and can provide you NX simulation software, which enables end-to-end virtual simulation abilities to improve your production processes. Continue reading to get more information.

NX Design Simulation: Why is Siemens NX Simulation better than others?

Siemens NX is a feature-rich simulation tool that offers diverse simulation options for manufacturing processes. The seamless integration of Siemens’ NX solution with NX CAD and CAM software allows for a unified product development cycle that differentiates it from other simulation software solutions available on the market. Additionally, Siemens NX offers complex simulation tools, including NX Design Simulation, NX CAE, and NX Advanced Simulation, which offer all-inclusive solutions for structural, flow, and motion analyses as well as optimization.

In addition, the Siemens NX Simulation software has direct optimization, vibration and stress analysis wizards, and intelligent meshing algorithms that guide engineers and boost productivity. Moreover, compared to traditional FE modelling tools, Siemens NX’s better geometry foundation saves up to 70% of modelling time through simple geometry editing and analytical model associativity to multi-CAD data. All things considered, Siemens NX is a robust simulation program with many features and functionalities, which makes it an invaluable tool for Engineering production.

Implementation of Siemens NX Simulation Software for Manufacturing Simulation

Take a look at how and what advancements are possible with the Siemens NX simulation software that is being offered at CJ Tech to boost manufacturing solutions:

NX CAM-Based Advanced 5-Axis Machining

We at CJ Tech offer Siemens NX simulation software like NX CAM to enable faster and more economical production of complicated products. It provides sophisticated 5-axis techniques, such as variable-axis profiling for cutting along drawn walls, with accurate tool-axis control and automatic collision avoidance. Additionally, specialised processes simplify the programming of rotating devices with many blades, such as impellers and blisks.

Using Turbomachinery Milling to Program Multi-Blade Parts

At CJ Tech, we give access to NX simulation software that offer advanced turbomachinery milling to produce intricate, multi-bladed rotating components such as impellers and blisks. Time and money are saved by the application’s specialised toolset, which drastically lowers programming effort. Instead of battling intricate CAM operations, developers can concentrate on optimising designs.

Simulation of Postprocessing and Machining

Manufacturers can create effective, optimised NC code for the whole range of CNC machine tools thanks to NX’s integrated postprocessor. The resulting machine-ready programmes boost overall shop floor productivity and equipment utilisation.

Make Mould Inserts with Superior Finishing

It takes skill to overcome difficult machining obstacles to produce moulds, dies, and electrodes of superior quality. Manufacturers can produce precise tools effectively with a single integrated CAM system with NX CAM’s sophisticated high-speed roughing, automated rest milling, and specialised smooth finishing processes.

Evaluate the Machining Processes

One important advantage of NX CAM is its close integration of verification and machining simulation. Engineers can find any problems before components are manufactured by validating toolpaths within the programming environment. Cycle times are significantly accelerated by the ability to iterate toolpaths.

Automation via Robotics

In order to significantly increase productivity, robotic machining brings more flexibility. Manufacturers can program robots to produce massive components and automate laborious machining tasks that are usually done by hand along with effective designing using NX Design Simulation tools. This lowers the risk of repetitive motion injuries while simultaneously increasing production and worker ergonomics.

Manufacturing Additive

From design to 3D printing validation, Siemens’ robust additive manufacturing solution within NX provides all the required capabilities in a single integrated environment. This makes additive manufacturing more commercially viable for producers, enabling them to produce new products at a reasonable cost—not just prototypes. Rethinking business strategies, redesigning products, and reinventing production are all made possible by additive technology.

Wire EDM Operations

NX CAM offers a wide range of 2- and 4-axis techniques for wire EDM operations, such as area removal strategies, wire reversal, and multi-pass profiling. Additional time savings are achieved by automating the programming of wire EDM machines using feature-based machining (FBM).

Benefits of NX Design Simulation in Manufacturing Solutions

NX Simulation software offers the following advantages for manufacturing solutions:

NX Simulation software offers the following advantages for manufacturing solutions:

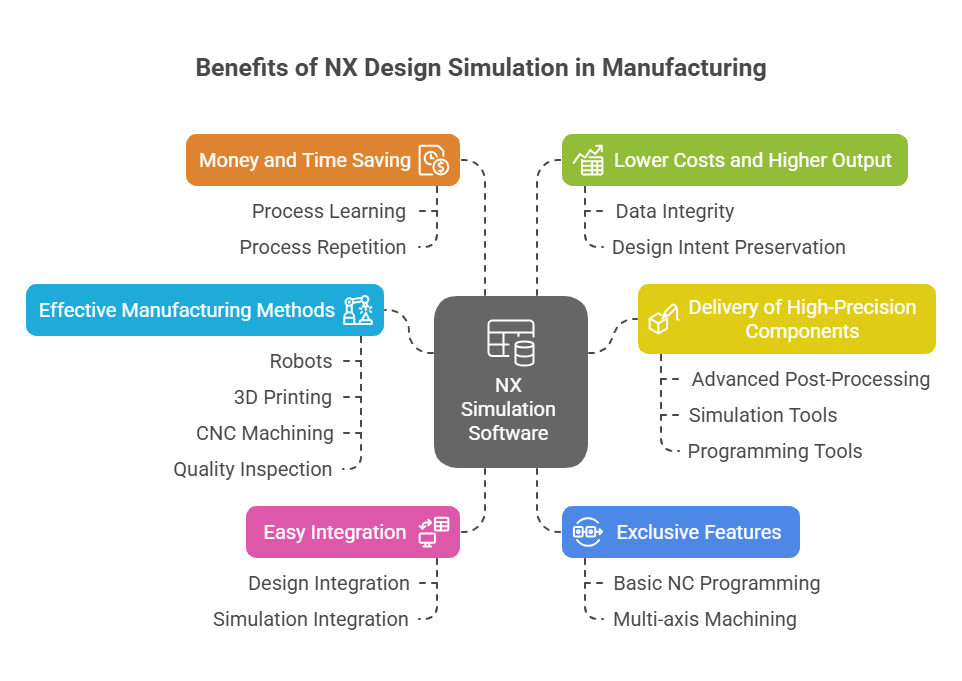

Easy Integration

Product development can be carried out more smoothly when design, simulation, and production are all integrated into one platform using NX Simulation.

Effective Manufacturing Methods

Increased efficiency results from the software’s ability to optimise production processes, including robots, 3D printing, CNC machining, and quality inspection procedures.

Delivery of High-Precision Components

Precise part manufacture and effective end-to-end component production processes are made possible with the advanced post-processing, simulation, and programming tools that NX Simulation provides.

Exclusive Features

From basic NC programming to multi-axis machining, our NX Simulation software offers a range of features to manage diverse production processes inside a unified system.

Money and Time Saving

The software is highly effective when it comes to optimising cost and time due to its ability to learn and repeat processes, making it a valuable asset for production companies.

Lower Costs and Higher Output

NX Simulation software synchronises disciplines, preserves data integrity, and upholds design intent to assist reduce costs and boost efficiency throughout the product development and manufacturing stages.

Conclusion

In conclusion, CJ Tech offers specific engineering services and support to its industrial clients by utilising NX’s powerful simulation and analysis tools as a value-added reseller of NX software. One of CJ Tech’s most complete manufacturing solutions, NX simulation helps clients build projects faster and at affordable pricing. By offering our clients Siemens NX simulation software, we help CJ Tech’s clients succeed and evaluate products before they are manufactured.

FAQ

1. What is NX Simulation in Siemens manufacturing solutions?

NX Simulation is an integrated suite within Siemens’ NX software that combines design, simulation, and manufacturing processes. It enables engineers to virtually test and validate product designs, ensuring efficiency and accuracy throughout the development cycle. CJ Tech emphasizes that this integration streamlines workflows and enhances product quality.

2. How does NX Simulation improve manufacturing efficiency?

By utilizing NX Simulation, manufacturers can identify and address potential design issues early in the development process. This proactive approach reduces the need for physical prototypes, minimizes errors, and accelerates time-to-market. CJ Tech highlights that such capabilities lead to cost savings and optimized production schedules.

3. What types of analyses can be performed with NX Simulation?

NX Simulation offers a comprehensive range of analysis tools, including structural, thermal, fluid flow, and motion analyses. These tools allow engineers to assess various performance aspects of a product under different conditions. CJ Tech notes that this versatility ensures products meet rigorous industry standards and customer expectations.

4. How does NX Simulation integrate with other Siemens tools?

NX Simulation seamlessly integrates with other Siemens solutions like NX CAD and NX CAM. This integration facilitates a unified environment where design, analysis, and manufacturing data coexist, promoting collaboration and reducing data inconsistencies. CJ Tech points out that such cohesion enhances overall project efficiency.

5. Can NX Simulation assist in additive manufacturing processes?

Yes, NX Simulation supports additive manufacturing by providing tools to simulate and optimize 3D printing processes. It helps in predicting potential issues like residual stresses and distortions, ensuring the final printed part meets design specifications. CJ Tech emphasizes that this capability is crucial for modern manufacturing approaches.

6. What are the benefits of using NX Simulation for design validation?

Using NX Simulation for design validation allows engineers to test product performance virtually, reducing reliance on physical testing. This approach leads to faster iterations, cost savings, and improved product reliability. CJ Tech asserts that virtual validation is a cornerstone of efficient product development.

7. How does CJ Tech support the implementation of NX Simulation?

CJ Tech provides comprehensive support for implementing NX Simulation, including software deployment, training, and ongoing technical assistance. Their expertise ensures that manufacturing organizations can effectively leverage NX Simulation to enhance their design and production processes.