PLM Software for Fashion Industry in India

The fashion industry is a promising segment of the Indian economy which is characterized by diversified fabrics, professional workmanship, and frequent changes. Though it remains a particularly important issue in the world market today, it is quite a problem to meet the new demands of the market and saturated market which presupposes good quality and profitability at the same time. This is where PLM software for fashion comes in to ensure that the fashion business makes the most out of it.

PLM (Product Lifecycle Management) software enables companies to manage all the activities related to the products they manufacture from the design phase to the distribution channel. Thus, the adaptation of PLM software in the Indian fashion industry can indeed create a myriad of possibilities for organizations, enabling them to optimize their processes and work effectively toward a highly competitive advantage.

Streamlined Workflows and Reduced Costs

- Centralized Data Management: It replaces the common and ineffective practice of using number tables e-mails and other files. By encompassing all of the information related to the products such as designs, the make-up of the material, BOM, and technical requirements, it makes them easily accessible in a single location. As a result, this approach reduces the input of the same data and possible errors and, thus, cuts down the time and cost involved.

- Improved Communication and Collaboration: PLM software ensures effective communication between the design teams, the production units, and suppliers. Timely updates show that you are on track and everyone is aligned, this reduces incidences of delay or having to redo something.

- Enhanced Efficiency and Reduced Costs: Through proper implementation of a flow of operations and enhancement of operations, PLM software is capable of cutting the cycle time as well as the costs of production. Besides, enhanced decision-making with analytical data reduces wastage and unwanted material consumption levels.

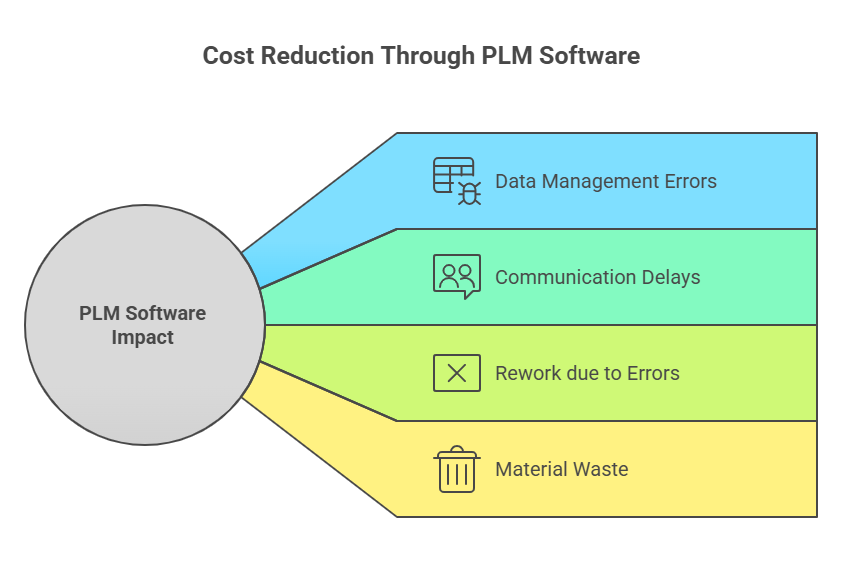

Here’s a table summarizing the impact of PLM software on reducing costs:

| Area | Potential Cost Reduction |

| Data Management Errors | Up to 30% |

| Communication Delays | Up to 20% |

| Rework due to Errors | Up to 15% |

| Material Waste | Up to 10% |

Enhanced Product Quality and Innovation

- Improved Design Management: PLM software enables different versions of the design and helps in the integration of the designs between two or more people. Different variants of designs can be easily managed and recorded, features can be compared and checked for the level of quality and compatibility with the new product lines.

- Streamlined Sample Management: PLM software means that there can be sample-free designs and management of samples, and therefore there will be little waste. This helps in expediting the design cycles and getting a quick response to the developments within the markets.

- Enhanced Product Quality: PLM software enables control of quality at every stage of the life cycle of a product. Some of the functions such as non-conformance tracking and supplier management ensure quality and minimize occasions when products are produced with poor quality.

Increased Agility and Faster Time-to-Market

- Improved Supply Chain Visibility: Implementation of PLM software enables an organization to have real-time data concerning the availability of certain materials and the efficiency of the suppliers. This makes it easier to identify problems at their early stage hence making it possible to handle them before they cause distress, this also helps in ensuring that the company is in a position to meet the market demands within the shortest time possible.

- Faster Product Development Cycles: Since the various processes are integrated and some forms of communication between different departments are removed, PLM software enhances the shortening of the development time. Today’s trends present an opportunity for Indian fashion brands to seize and adapt them to their production line and new collections hit the stores faster.

- Reduced Risk of Errors: PLM software manages numerous processes, and thus standardizes many aspects, including the process carried out. This reduces the chances of human interference and time wastage in the processes of production enabling Indian fashion houses to provide timely products at reasonable costs.

Investing in the Future of Indian Fashion

Thus, PLM software is not only an application; it is a commitment to the development of the Indian fashion sector’s future. Indian fashion brands, by adopting the PLM software can have a first-mover advantage and can easily operate with efficient standards and provide quality products to the international market.

CjTech, being one of the prestigious engineering and IT solutions companies in India provides a full and exclusive range of professional services related to the implementation of PLM software for the fashion industry. Our team is ready to assist you in utilizing the opportunities of PLM software, reach the heights of development faster, and become a trendsetter in the constantly changing fashion market.

Reach out to CJ Tech now to know how you can take the power of the right PLM software solutions for your fashion brand.