Innovation in the highly competitive aerospace industry is no longer a luxury. Aerospace manufacturers need to innovate constantly. They are compelled to deliver at quick speed lighter and smarter products. This requires a seamless fusion of technologies-design, simulation, and manufacturing. Siemens NX offers exactly that.

Siemens NX Software eliminates traditional silos between disciplines and departments. Engineers and manufacturers can now innovate faster. They can also improve product quality.

THE CHALLENGE OF AEROSPACE PRODUCT DEVELOPMENT

Aerospace industry is a highly complex industry. It faces some of the most complicated engineering challenges.

Like,

- Demand for lightweight and sustainable materials.

- Extreme tight tolerances and regulatory requirements.

- Extended supply chains. That involves numerous stakeholders.

- Increasing product complexity. This includes embedded systems and software.

To tackle these challenges, advanced tools are required. That can manage complexity and actively drive innovation. Siemens NX offers precisely that-a digital thread connecting with a single, integrated environment every phase of the development process.

ACCELERATING AEROSPACE INNVOATION

Here’s how Siemens NX Software helps to accelerate aerospace innovation.

SEAMLESS INTEGRATION FROM CONCEPT TO PRODUCTION

Siemens NX Software has the ability to unify under one digital roof diverse engineering tasks.

Traditional aerospace development often involves disconnected tools for:

- CAD (Computer-Aided Design);

- CAE (Computer-aided engineering); &

- CAM (Computer-aided manufacturing).

This fragmentation results in inefficiencies and delays. There is also the additional risk of errors.

Siemens NX on the other hand integrates all of these into a single solution. This way it enables teams to work across functions collaboratively.

- DESIGN (CAD): Creates complex parts, assemblies, and systems with high precision.

- SIMULATION (CAE): Uses advanced structural, thermal, and flow analysis. This helps to validate performance.

- MANUFACTURING (CAM): Automates and optimizes manufacturing processes. For CNC engineering, additive manufacturing, and more.

Changes made at any stage with Siemens NX get automatically replicated across the entire model ensuring consistency. This helps to reduce rework.

AEROSPACE-GRADE CAD CAPABILITIES

The design stage for aerospace development is critical. It is where even the smallest design flaw can lead to significant downstream issues.

Siemens NX offers powerful CAD tools. They are specifically tailored for aerospace applications.

- ADVANCED SURFACE MODELING: For aerodynamic components. Like wings and fuselages.

- PARAMETRIC AND DIRECT MODELING: Accommodates late-stage design alterations.

- MULTIDISCIPLINARY INTEGRATION: Facilitates seamless collaboration between teams. They can effectively co-design complex systems.

- DIGITAL TWIN SUPPORT: Allows engineers to work with physical products’ virtual replicas.

Aerospace companies can by using Siemens NX Software in the design phase create from the outset more innovative and efficient products.

SIMULATION-DRIVEN DESIGN

Simulation in the aerospace sector is not just about validation step. It is also about functioning as an innovation driver. Engineers can test performance continually with Siemens NX simulation fully embedded into the design environment as the design evolves.

Siemens NX key capabilities include:

- Structural and vibration analysis for aerospace loads.

- Thermal simulation for high speed and space environments.

- Aerodynamic flow simulations using integrated CFD tools.

- Multiphysics simulation for advanced composite materials and embedded systems.

This integrated simulation environment ensures design decisions are taken early in the development process on the basis of real-world performance metrics. They help to drastically reduce the need for expensive prototypes and physical tests.

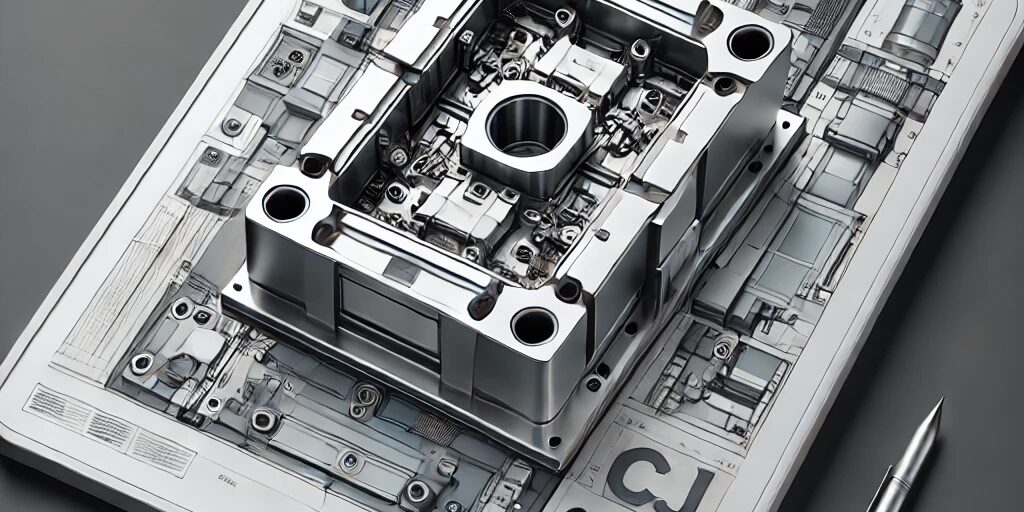

ADVANCED MANUFACTURING WITH SIEMENS NX CAM

Once the design is finalized the focus shifts to manufacturing. In manufacturing, efficiency, precision, and quality are essential.

Siemens Software NX features a robust set of CAM tools. Aerospace manufacturers using them can seamlessly move to physical product from digital design.

KEY MANUFACTURING CAPABILITIES

- 5-axis and multi-axis CNC machining.

- Automated feature recognition and toolpath generation.

- Additive manufacturing integration. For lightweight structures and complex geometries.

- Tooling and fixture design. For jigs, molds, and assembly aids.

- Post-processing and machine simulation. It ensures G-Code accuracy before deployment.

BENEFITS

- Faster load times.

- Reduced production costs.

- Higher-quality output with lesser iterations.

SUPPORTING AEROSPACE COMPOSITES & MATERIALS

Composite materials offer significant strength-to-weight advantages. That is highly essential to modern aerospace components. However, they introduce new challenges in design and manufacturing.

To address them, Siemens NX offers specialized tools.

- Automated flat pattern generation for manufacturing.

- Simulation of demanination and failure scenarios.

- Manufacturing support. For fiber placement and tape-laying machines.

This deep integration of material-specific features allows engineers to take without compromising manufacturability, maximum advantage of new materials

DIGITAL TWIN AND DIGITAL THREAD IN AEROSPACE

Digital Twin is revolutionizing aerospace sector. It indicates a virtual representation of a product that resembles its physical counterpart in real-time.

Siemens NX Software facilitates the creation of high-fidelity digital twins spanning from design to operations. The digital thread in parallel ensures all stakeholders have throughout the product lifecycle to a single source of truth.

These technologies together

- Improve traceability and compliance.

- Enable predictive maintenance and performance monitoring.

- Support over-the-air updates; and in-service design refinements.

Aerospace companies can by leveraging these technologies extend innovation beyond the factory floor. They can extend it to the operational lifespan of aircraft and spacecraft.

COLLABORATION AND SCALABILITY IN A GLOBAL INDUSTRY

Aerospace projects are often geographically dispersed. They involve global teams and suppliers.

Siemens NX

- Supports cloud-based collaboration.

- PLM integration with Teamcenter.

They enable across continents efficient data sharing and version control. Additionally features like real-time co-design and access controls with change management workflows ensure even the most complex projects stay compliant and on track.

Aerospace companies by adopting Siemens NX will be investing in a software platform that’s robust and reliable. They will also be securing a competitive edge in the next decade of aviation and spaceflight.

CONCLUSION

In aerospace, Innovation is not just about engineering excellence. It also requires an end-to-end digital approach that’s tightly integrated.

Siemens NX Software offers the right blend of tools and scalability. They help design, simulate, and manufacture cutting-edge aerospace products within a unified environment.

Organizations can by leveraging CJ Tech’s Siemens NX capabilities, reduce costs and accelerate timelines. They can also improve product quality.

FAQs

1. In what way Siemens NX Software supports aerospace innovation?

It

- Enables faster and more accurate design iterations, simulation, and validation of aerospace components.

- Integrates in a single environment, CAD, CAE, and CAM.

They help reduce development time; enhance performance; and optimize manufacturing processes. All of these are essential for aerospace innovation.

2. How is aerospace product lifecycle streamlined by Siemens NX?

It streamlines by offering a unified platform. Teams using it can

- Design complex 3D models.

- Simulate aerodynamic and structural performance.

- Plan and validate manufacturing operations.

- Collaborate with PLM integration in real-time.

These will reduce errors and ensure data integrity from concept through to manufacturing.

3. Can aerospace systems’ complexity be handled by Siemens NX Software?

Yes. Siemens NX software is designed to

- Handle aerospace products’ high complexity. This includes advanced assemblies, intricate aerodynamics; and embedded systems.

- Supports system-driven product development. This will allow engineers to manage through modularity and configuration complexity.

4. Is Siemens Software NX compatible with existing systems and industry standards?

Yes.

Siemens NX

- Supports a wide array of industry standards. Like for instance, STEP; JT; and IGES.

- Integrates with enterprise systems. Like Teamcenter.

These will ensure compatibility with supply chain partners and legacy tools.

5. Can I use Siemens NX for commercial and defense aerospace projects?

Yes, you can. It is in fact used by leading aerospace companies in commercial and defense sectors. Its compliance with industry requirements and security features with flexible scalability makes it ideal for a wide array of aerospace programs.