As the twenty-first century goes on, there will be a major transformation in the industrial sector. A crucial component of this development is the growth of applications for computer-aided manufacturing (CAM). Initially, CAM systems mainly focused on automating the manufacturing process, but they have developed into sophisticated hubs of creativity that combine modern technology to enhance productivity and make production easier. In this blog, let’s explore the major developments and trends influencing CAM software going forward, with a focus on the role that industry pioneers like Siemens CAM are playing in advancing these developments.

Advanced Robotics and Automation

Industrial Revolution Using Self-Driving Systems

The growing integration of robots and sophisticated automation is one of the most interesting topics in the future of CAM. Robotic machining systems that can function with little assistance from humans are getting closer to becoming a reality. These systems use machine learning (ML), artificial intelligence (AI), and real-time data analytics to optimize industrial processes and adjust to changing conditions.

Siemens CAM software leads the robotics industry by offering capabilities that facilitate smooth communication between CAM systems and robots. These robots can perform intricate operations with unmatched accuracy, increasing production productivity and flexibility. For example, in a contemporary aircraft plant, robots with Siemens CAM technology can precisely perform complex operations like cutting and assembling composite materials, minimizing human error and increasing productivity.

Green Manufacturing and Sustainability

Making the Most of a Greener Future

Sustainability is just as important to CAM’s future as productivity and efficiency. Green manufacturing methods are being supported by CAM software, which is changing as environmental concerns throughout the world intensify. This entails encouraging energy-efficient machining techniques, reducing waste, and maximizing material utilization.

Siemens CAM, by incorporating sustainability into its software solutions, is leading the way in this field. By using sophisticated simulation and optimization technologies, manufacturers may drastically cut down on energy and material waste. For example, Siemens CAM enables producers to model the complete machining process to spot inefficient processes and remove them, therefore lowering the production’s overall carbon footprint.

Furthermore, there is a growing movement towards circular manufacturing techniques, which reduce waste and repurposed materials. Manufacturers can save costs and protect the environment by using CAM systems in the design and management of these processes.

Digital Twin Implementation

Connecting the Digital and Physical Worlds

The use of digital twin technology is poised to completely transform how we approach manufacturing innovations. CAM software facilitates comprehensive virtual testing, simulation, and real-time performance monitoring by generating virtual copies of actual assets, including machines and whole production systems. This feature speeds up time to market, lowers the cost of prototyping, and improves machine performance.

Digital twin technology is being implemented by Siemens CAM, a pioneer in the field. Predictive maintenance and operational efficiency can be achieved by using the very precise digital twins created by their software. For example, a CNC machine’s digital twin can be utilized to plan maintenance ahead of time, anticipate wear and tear, and enhance machining operations for increased efficiency.

Digital twins offer a full perspective of manufacturing processes, which helps to enhance decision-making as well. Manufacturers can confidently apply the modifications they make in the virtual world—which includes simulating various scenarios in the real world. This improves industrial processes’ agility while also decreasing downtime.

Integrating Industry 4.0 with IIoT integration

Accepting the Networked Manufacturing

A new age of linked production is being driven by the amalgamation of CAM software with the Industrial Internet of Things (IIoT) and Industry 4.0 concepts. Better data gathering, analysis, and predictive maintenance are made possible by the real-time monitoring, management, and optimization of industrial processes made possible by this connection.

Siemens CAM, for example, offers tools that integrate production systems, machines, and sensors into a coherent, smart network and is completely compliant with Industry 4.0 requirements. Real-time insights into production processes and continuous data flow are made possible by this connection. Siemens CAM can link many production lines and offer real-time machine performance data in an automobile plant, assisting in the prevention of bottlenecks and optimization of production flow.

The combination of IIoT and CAM improves the capacity for predictive maintenance as well. CAM systems may minimize downtime and increase equipment lifespan by predicting when maintenance is required based on data analysis from linked instruments. The transition from reactive to proactive maintenance represents a noteworthy advancement in terms of operational efficiency.

Artificial Intelligence and Machine Learning

Intelligent Manufacturing Processes

These days, machine learning and artificial intelligence are essential parts of contemporary CAM software. These technologies promote continuous improvement in manufacturing processes by enabling real-time data analytics, adaptive machining procedures, and predictive maintenance.

In terms of AI integration, Siemens CAM is at the forefront. Their software analyses massive volumes of data from machining operations and makes optimization recommendations using machine learning methods. To ensure constant quality and efficiency, Siemens CAM, for example, may automatically modify machining settings in real time to account for fluctuations in material qualities or tool wear.

AI is also essential for improving decision-making. Through historical data analysis and pattern recognition, CAM systems can provide manufacturers with valuable insights to enhance their workflows and output. As a result, there is a cycle of continual development whereby each manufacturing run is carried out with increased efficiency.

Improved Usability and Easily Accessible

Democratizing Modern CAM Features

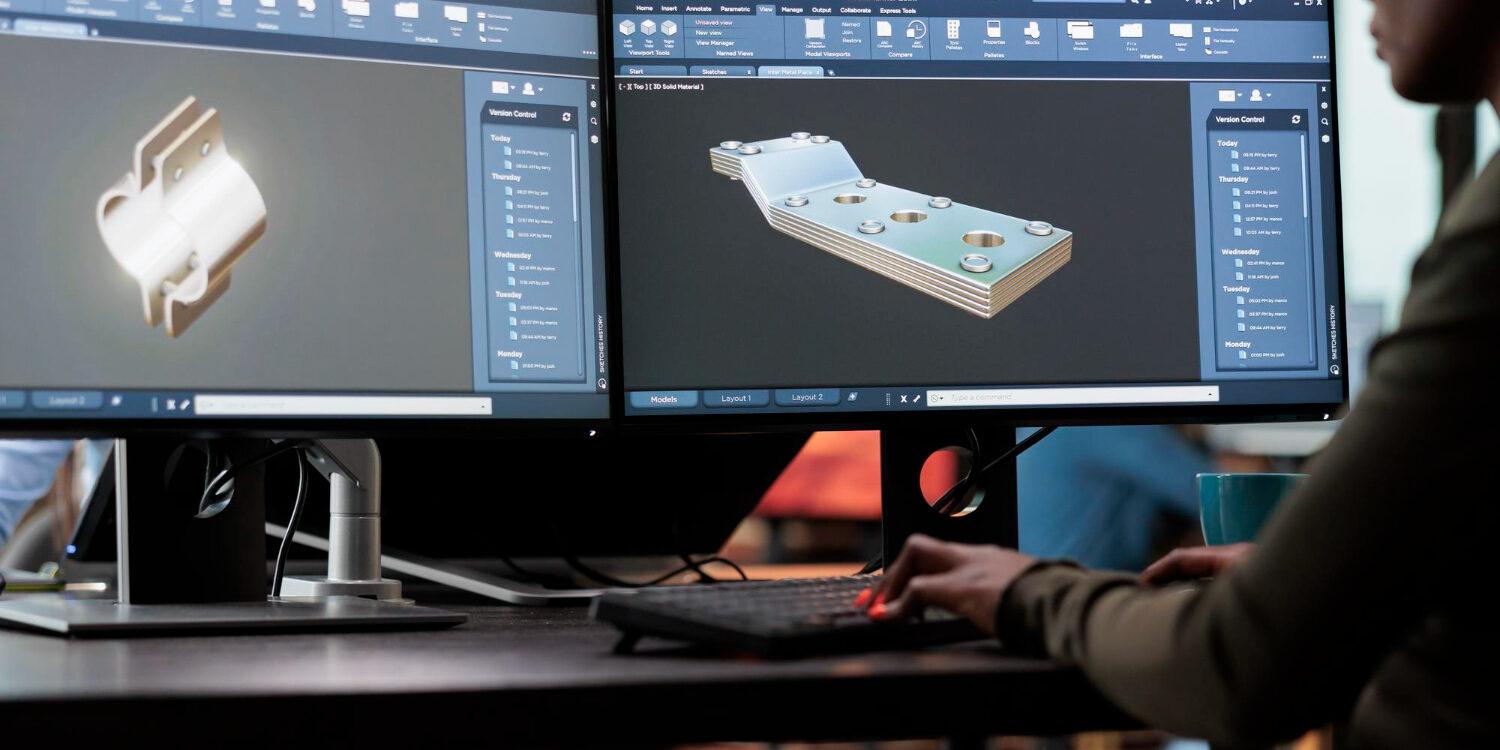

As CAM software advances, improving accessibility and user experience is becoming more and more important. With their cloud-based accessibility and user-friendly interfaces, modern CAM systems are getting easier to operate. This development is democratizing the use of powerful CAM capabilities, and facilitating the adoption of modern technologies by smaller enterprises.

Siemens CAM provides cloud-based solutions that easily interface with other design and manufacturing tools, making it an excellent example of this trend. This lowers IT expenses while also enhancing teamwork. Using a shared cloud-based platform, a production team may prepare the CAM procedures in one location while a design team works on a CAD model in another.

Furthermore, the emphasis on user-friendly interfaces makes it possible for even non-technical users to efficiently utilize complex CAM capabilities. This is especially important for small and medium-sized businesses (SMEs), who wish to compete with large companies in terms of production capability but may not have the funds to engage specialized CAM operators.

Conclusion

In conclusion, Computer-Aided Manufacturing (CAM) software is expected to revolutionize the manufacturing sector in the future with its advanced automation, sustainability, digital twin technology, and improved user experiences. These improvements are being pioneered by industry giants like Siemens CAM, which provide tools that increase manufacturing processes’ accuracy, efficiency, and inventiveness. CAM software will be essential in helping to transform manufacturing into a more connected, intelligent, and sustainable enterprise as these CAM trends develop. Manufacturers will be well-positioned to lead and prosper in the cutthroat environment of contemporary industry if they keep ahead of the curve and adopt these manufacturing innovations.

Get in touch with CJ Tech for knowledgeable assistance and solutions when using Siemens technology to transform your manufacturing operations.