Digital transformation is in the era of Industry 4.0, no longer a luxury. It has become a necessity. Manufacturing companies across the globe are leveraging advanced technologies to stay agile and responsive to market demands. NX Manufacturing, a comprehensive Siemens solution is driving this change. It integrates product design with engineering and manufacturing into a unified digital thread.

Siemens NX has emerged as a key enabler with manufacturers seeking to reduce production costs and shorten development cycles. Additionally, NX CAM Software, a vital component of the broader NX for Manufacturing offers powerful capabilities. They enhance operational efficiency on the shop floor.

NX MANUFACTURING

Its’ designed to streamline and optimize the entire manufacturing process. Siemens NX provides from CAD to CAM and CAE, a fully-integrated environment. They bridge the gap between product development and production.[-

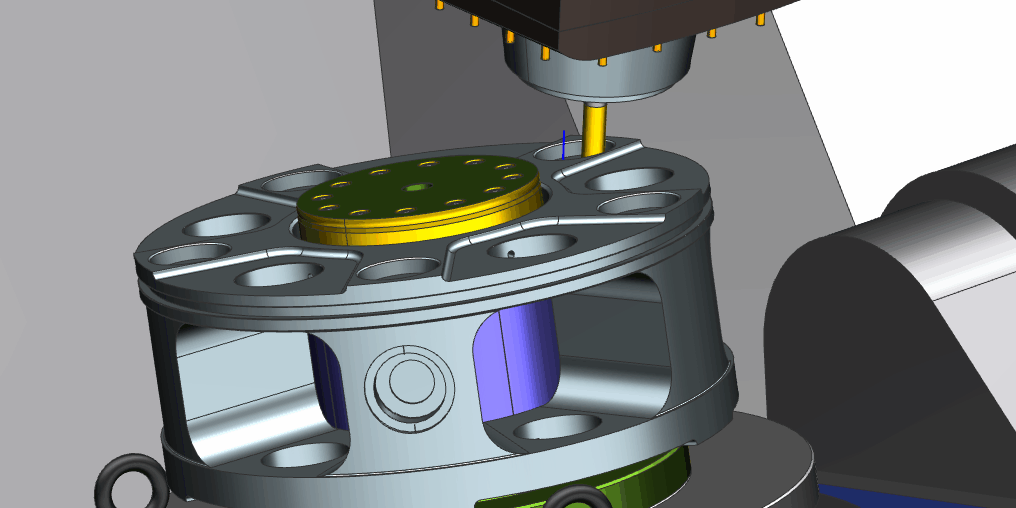

It empowers with its robust NX CAM Software, manufacturers to program CNC machines and simulates machining operations. It also empowers manufacturers to validate tool paths, all within a single platform. This unified approach significantly reduces errors and accelerates time-to-market. They ultimately help to boost productivity.

HOW NX MANUFACTURING IMPROVES EFFICIENCY?

Modern factories face enormous challenges. Like for instance, demand for customization, shorter product lifecycles, and above all, skills gap in the workforce.

The following tells how NX Manufacturing addresses these issues to driver greater operational efficiency.

STREAMLINED WORKFLOWS

Traditional manufacturing often involves siloed departments using disconnected tools. They cause redundant data entry, leading to miscommunication and inefficiencies. All functions from design and simulation to production with NX for Manufacturing are through a unified platform, connected. This integration simplifies workflows. They also facilitate cross-functional collaboration. All of these drive throughout the product lifecycle, data consistency. Engineers and machinists work from the same model. This helps to reduce misunderstandings and accelerate decision-making.

REDUCED PROGRAMMING TIME

CNC Programming is traditionally a time-consuming task. They can especially be more so for complex parts.

NX CAM Software cuts programming time significantly through,

- Feature-based machining. This automates toolpath generation based on part geometry.

- Template-driven processes. For repetitive operations.

- Associative tool paths. That updates automatically with design changes.

These automation features save time. They also allow less experienced programmers to generate high-quality CNC code efficiently.

MINIMIZED ERRORS AND REWORK

Mistakes in the digital plan can result in physical defects. They also lead to wasted materials and machine downtime.

Siemens NX tackles this issue with,

- Integrated simulation tools. That verifies tool paths in a virtual environment.

- Collision detection. That prevents crashes and tool breakage.

- Machine-specific post-processing. That ensures output is tailored to actual hardware.

Overall, proactive validation ensures issues are detected early. This will help to dramatically reduce the need for rework.

OPTIMIZING MACHINING STRATEGIES

NX CAM Software offers cutting-edge machining strategies. Like for instance, adaptive milling and high-speed machining. These techniques help to optimize material removal rates.

They also maximize tool wear leading to

- Faster cycle times.

- Extended tool life.

- Better surface finish.

The software can also optimize feed rates and cutting conditions based on the material and geometry. This further improves efficiency.

SCALABILITY AND FLEXIBILITY

Modern production environments need to scale quickly. They also need to adapt to new challenges. NX Manufacturing be it for producing a single custom part or mass producing components, adapts to fit. Manufacturers can customize from aerospace to automotive and medical devices, the NX environment to support different processes and standards.

FUTURE-READY MANUFACTURING WITH NX

NX Manufacturing is not just a solution for today. It is built with the future in mind.

The following tells how it aligns with emerging trends,

- DIGITAL TWIN AND SMART MANUFACTURING: Manufacturers can by creating a digital twin of products and production systems, stimulate and optimize every aspect of the operation. Siemens NX enables real-time feedback and predictive maintenance. They reduce downtime. At the same time, enhance overall equipment effectiveness (OEE).

- ADDITIVE AND HYBRID MANUFACTURING: NX supports additive manufacturing. This enables companies to design and fabricate complex parts with minimal material waste. Additionally, its ability to combine in one environment, additive and subtractive processes, gives manufacturers a competitive edge.

- AI AND AUTOMATION: Ongoing developments in AI are being incorporated into NX CAM Software. They offer intelligent recommendations with automated feature recognition and predictive analytics. Manufacturers with these capabilities can make smarter decisions faster.

CONCLUSION

NX Manufacturing has emerged in a world where speed and precision define manufacturing, as a cornerstone of digital transformation. Siemens NX by providing an integrated, intelligent, and automated solution, enables modern factories to streamline operations, and reduce costs. They can also respond quickly to market demands.

NX for Manufacturing delivers the tools, whether it’s running a high-volume automotive line or producing a one-off aerospace component, that’s required to optimize performance and ensure sustainable growth. By leveraging CJ Tech’s capabilities in NX for Manufacturing, you can make smart manufacturing decisions. Investing in NX CAM Software is essential for your company aiming to future-proof its operations and stay competitive.

FAQs

1.How can I improve my factory efficiency with NX CAM Software?

It helps you enhance your factory efficiency by,

- Automating repetitive tasks. Like Toolpath Generation.

- Reducing machining errors. With accurate simulation.

- Optimizing tool usage and cutting strategies. This helps to save time and materials.

- Allowing quick revisions and updates. To manufacturing plans.

2. What benefits does Siemens NX for Manufacturing offer?

Siemens NX for Manufacturing offers ample benefits. Like,

- Seamless integration between design and manufacturing.

- Faster product development cycles.

- Reduced production downtime. Due to better planning and simulation.

- High-precision machining. With advanced multi-axis capabilities.

- Support for additive manufacturing. Also, hybrid processes.

3. Will I be able to reduce costs with NX for Manufacturing?

Yes, it can help reduce costs significantly by,

- Minimizing waste. Through precise material usage.

- Shortening lead times. With faster NC programming.

- Lowering the number of physical prototypes. Through virtual validation.

- Improving machine uptime. Via optimized machining processes.

4. Does NX Manufacturing suit small and medium factories?

Yes. They are scalable. Solutions can be tailored to meet specific requirements of small or medium factories. They also cater to large factories requirements. Additionally, businesses using its modular structure can invest in tools they require. The tools will also come in handy as their business operations grow and expand.