Complexity in aerospace programs is a constant. The more complex it gets, the more difficult it becomes to manage it.

This poses a huge challenge- how to manage them all from scores of components and sub systems to stringent quality and regulatory requirements, and more, without losing control over cost and quality? That’s where Teamcenter PLM and the Digital Thread comes in.

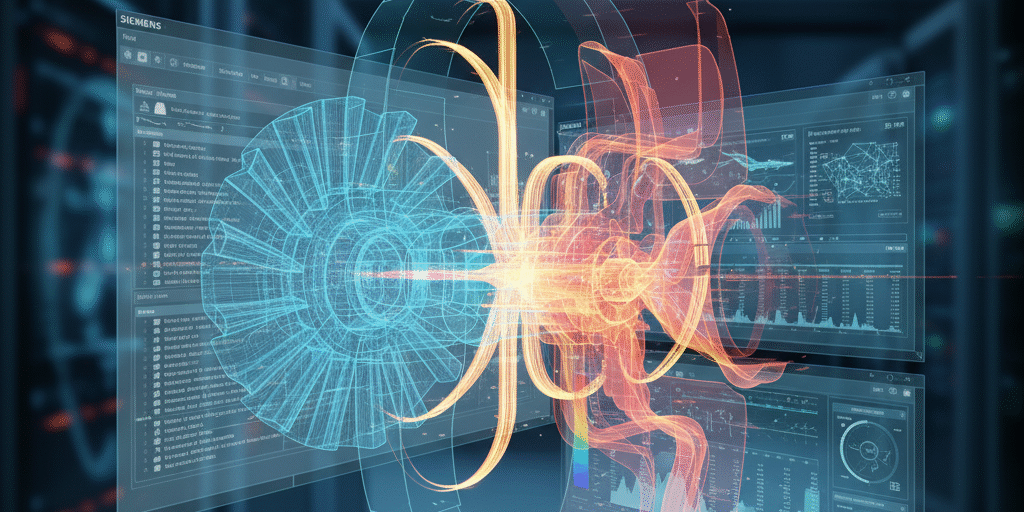

Siemens Teamcenter PLM software when properly implemented can function as the backbone tying together every stage of the aerospace program. This helps create traceability, visibility, and agility.

WHAT MAKES AEROSPACE PROGRAMS COMPLEX?

The following tells what makes it so complex:

- SCALE & SCOPE OF PARTS & VARIANTS: Aerospace systems comprise often millions of parts. Many with variants or alternate configurations for varied models or mission profiles. Managing all these variants is critical. They require proper coordination. If that is done, they ensure proper versions and avoiding mistakes.

- REGULATION, SAFETY, CERTIFICATION NEEDS:

- Compliance with regulations like FAA, EASA, etc standards. These need rigorous documentation, traceability, testing, and change management.

- Early detection of issues. Like design or manufacturing errors or program delays or other related safety issues.

- LONG LIFECYCLE & SUSTAINMENT: Aerospace products have many phases. They span from concept to design, testing, deployment, and more. This requires preservation of data. They also need to be made accessible and accurate across decades.

- GLOBAL SUPPLY CHAIN & COLLABORATION: Parts, subsystems, etc, often come from multiple suppliers. Most are based in different geographies. This requires ensuring everyone is using the right data. Also, require changes to be communicated properly with traceability.

- CHANGE & INNVOATIION PRESSURE: Aerospace programs from time to time evolve. There will be new requirements; new technologies like software, additive manufacturing, etc; and mew missions. Handling change without expending more cost or timeline can be difficult. They require robust systems.

The above shows why managing complexity is not optional. It is something organizations must handle with dexterity.

WHY DIGITAL THREAD MATTERS?

The following tells why it matters:

- TRACEABILITY: Can trace through to its implementation, validation, change history, and impact, any feature or requirement.

- CONSISTENCY: Provides a single source of truth. This eliminates duplicated data and fewer version mismatches.

- VISIBILITY: Allows stakeholders like system engineers, suppliers, etc, see where things stand. They also get to see what changed and what is due.

- AGILITY & DECISION SUPPORT: Allows evaluation of impact across the chain when change is required (like design insight, mission change). Then, helps drive response quickly.

PLM Software is the platform to enable this digital thread. Among the varied PLM software options, Siemens Teamcenter PLM is designed to manage product lifecycle integrating many functions, domains, and stakeholders.

HOW TEAMCENTER’S DIGITAL THREAD HELPS MANAGE & REDUCE COMPELXITY?

The Digital Thread enabled by Siemens Teamcenter PLM helps aerospace programs in multiple ways manage complexity.

SINGLE SOURCE OF TRUTH REDUCES ERRORS:

- Provides one integrated PLM software rather than multiple disconnected tools or duplicated files or fragmented data repositories.

- Allows teams-design, manufacturing, supply chains, quality safety- to refer the same data.

- Reduces iteration loops, integration bugs, and miscommunication.

FASTER AND MORE INFORMED CHANGE MANAGEMENT:

- Allows analysis across requirements, design, simulation, supplier parts, cost, and schedule. This is essential when change is proposed, like regulation change, etc.

- Gives program leaders’ early warning and options. Rather than reacting late and at high-cost.

BETTER COMPLIANCE & REDUCED AUDIT RISK:

Often out-of-compliance issues arise. Like missing traceability, misaligned data, etc. Using Teamcenter PLM, teams can

- Link and trace all artifacts (requirements, models, test results, changes).

- Generate audit reports, and proof of compliance faster and more reliably.

SIMULATION & DIGITAL TWIN ENABLE VIRTUAL VALIDATION:

Physical validation is expensive as well as time-consuming. Using simulation and digital twin technologies (integrated via Teamcenter),

- Allows earlier validation, testing, and correlation with test data.

- Reduces rework by catching issues early.

STREAMLINED SUPPLIER INTEGRATION & SUPPLY CHAIN RESILIENCE:

- Helps spot delays and quality issues early. By sharing configuration, variant, and requirements data with suppliers early.

- Helps facilitate alternate sourcing or managing supply risk.

SCALABILITY ACROSS PROGRAMS & LIFECYCLE:

Aerospace programs run long. At times, even run for decades. Using PLM system as part of a living digital thread helps,

- Retain memory. That is, what was built, certified, in service, upgraded.

- Supports sustainment, upgrade, and safety throughout life.

IMPROVED PROGRAM MANAGEMENT & VISIBILITY:

Teamcenter’s digital thread together with program planning and execution modules,

- Allows leadership to get clear dashboards of cost vs. schedule vs. risk vs quality.

- Helps ensure greater transparency leading to better decision-making, risk mitigation, and resource allocation.

The well-known American defense company Lockheed Martin Aeronautics, has leveraged digital thread concepts tied through PLM and MES (manufacturing execution systems) to modernize aircraft manufacturing.

The digital thread helps the company to

- Integrate engineering with manufacturing execution (shop floor).

- Ensure better visibility of part variants, tooling, supplier input, production planning, and handoffs.

ROLE OF SIEMENS TEAMCENTER PLM IN FUTURE AEROSPACE INNOVATION

The demands of aerospace programs in the future are only likely to grow. As a result, there will be more software content and autonomy; and greater use of digital twins and AI. Rapid development cycles and modular architectures will become more prevalent.

Teamcenter PLM is well-equipped to help meet these challenges ahead.

- DIGITAL TWINS IN OPERATION & SUSTAINMENT: Future could see more aerospace platforms stay in service longer. As such, collecting operational data, feeding it back into design cycles for upgrades, predictive management, will become vital. Digital thread will ensure operational feedback is captured and later tied back to design and requirements.

- MODEL-BASED SYSTEMS ENGINEERING (MBSE): Shift toward MBSE indicates several decisions (regarding system architecture, trade-offs) occur virtually before committed to hardware. Teamcenter helps to manage models. This links them to requirements, simulation, and others.

- AI/DATA ANALYTICS: With a well-populated digital thread, Big Data from design, to test, operations, etc, can be used to drive insights. Like predict failure modes, optimize designs, and reduce weight and cost, etc.

- SUSTAINABLE & LIFECYCLE COST: More focus is emphasized today through lifecycle thinking on minimizing environmental impact. Teamcenter helps

- Track materials, supply chain, usage, maintenance, and end-of-life.

- Support decisions that can minimize carbon footprint and improve recyclability.

CONCLUSION

Modern aerospace programs are multi-dimensional. There is high-risks and serious constraints, Managing complexity is no more an optional. It is a safety and competitive necessity.

PLM Software like Siemens Teamcenter PLM offers valued benefits when used to build a robust digital thread.

It

- Provides the framework to all the facets together-design, requirements, suppliers, simulation, and certification.

- Brings traceability, visibility, and agility.

This will help aerospace organizations to

- Reduce rework;

- Speed-up certification;

- Collaborate across supply chains; and

- Innovate faster.

By leveraging CJ Tech’s expert capabilities, your organization can embrace the digital thread via Teamcenter. This will help it face escalating complexity better.

FAQs

1.In aerospace programs, how does Teamcenter help manage complexity?

A.Teamcenter PLM simplifies the management of complex processes and collaboration. By leveraging PLM software, it

- Provides a unified platform for data, processes, and collaboration.

- Connects teams across engineering, supply chain, manufacturing, and quality control.

- Helps reduce silos, improve decision-making, and accelerate program execution.

2. Can Teamcenter PLM be integrated with existing aerospace engineering tools?

Yes. Teamcenter PLM offers strong integration capabilities. It

- Connects with leading CAD, CAM, CAE, and ERP systems.

- Allows aerospace companies to preserve existing investments.

- Enhances data continuity and collaboration across disciplines.

3. How is compliance in aerospace and defense sectors supported by Teamcenter?

Compliance in aerospace is critical. Teamcenter supports this by

- Enabling full traceability of requirements, changes, and certifications.

- Helping users using Siemens Teamcenter PLM track and audit every decision and design evolution. This ensures readiness for regulatory inspections and audits like EASA, ITAR, etc.

4. What role in product lifecycle visibility does Teamcenter’s Digital Thread play?

The Digital Thread powered by Siemens Teamcenter PLM

- Provides end-to-end visibility into product data- from initial concept to in-service performance.

- Ensures all stakeholders work with a single source of truth. This will reduce errors and speed up innovation.

5. How is cross-functional collaboration supported by Teamcenter in aerospace programs?

Teamcenter PLM breaks down departmental silos. This it does by

- Connecting data and workflows across all functions.

- Facilitating collaboration in real-time between all stakeholders-from engineers to suppliers and quality teams-using shared data models; and centralized processes enabled by the PLM software.