Product design landscape is rapidly evolving. As a result, designers and engineers with manufacturers face considerable challenges. There is enormous pressure on them to create high-quality products with precision and speed. To cope with these demands, there’s a constant need for better, more efficient tools. This is where CAD Software plays a prominent role. Among the many CAD Software variants, NX CAD Software occupies a prominent spot. A product of Siemens, it has been for years driving businesses to push the boundaries of innovation.

WHAT IS NX CAD SOFTWARE?

NX CAD, powerful CAD software developed by Siemens is among the most advanced CAD tools.

It offers for design, engineering, and manufacturing, integrated solutions. They help streamline from concept to production the entire product development process.

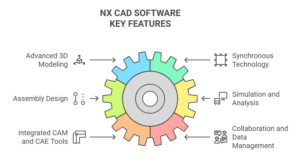

NX CAD SOFTWARE KEY FEATURES

ADVANCED 3D MODELING:

- Offers a range of powerful tools. They help create intricate 3D models. From individual components to complex assemblies, these models can be used to represent everything.

- Supports parametric and direct modeling techniques. Designers can now create and modify designs the way they want to.

SYNCHRONOUS TECHNOLOGY:

- Combines the best of parametric with the best of direct modeling.

- Allows designers to work with existing designs, make changes to geometry, and apply design intent. All without having to follow a rigid, step-by-step process.

ASSEMBLY DESIGN:

- Offers robust assembly design tools. They help streamline the creation and management of complex product assemblies. And also, facilitate their simulation. Potential issues can be identified early on in the design process.

- Handles large, complex assemblies. With hundreds or even thousands of parts.

SIMULATION AND ANALYSIS:

- Offers built-in tools. They help simulate product performance under varied conditions.

- Allows designers and engineers to test designs before they are physically manufactured. This ensures products perform as expected. And meet quality standards.

INTEGRATED CAM AND CAE TOOLS:

- Integrates CAD and CAE tools.

- Allows manufacturers to use the same platform for designing, and simulating products. Also, for manufacturing the products. This reduces the need for multiple software packages. Instead, ensures seamless transition from design to production.

COLLABORATION AND DATA MANAGEMENT:

- Provides tools for sharing designs, They are also used to track revisions, and manage data.

- Facilitates collaboration. Among design teams, manufacturers, and other stakeholders. This ensures everyone is on the same page.

- Enables projects move forward. Without delays or miscommunications’.

WHAT IS NX CAD USED FOR?

An extremely versatile tool, NX CAD is used to design a wide array of products across many industries. It can from aerospace to automotive, consumer electronics, and more, handle any product design process’ demands.

The following details for what is NX CAD Software used for.

PRODUCT DESIGN:

- Offers the tools to create accurate, high-quality models. Used for designing products in 3D, be it a simple mechanical part OR a complex multi-component system.

- Handles complex shapes, assemblies, and deign intent. This makes it great tool for product designers.

PROTOTYPING & SIMULATION:

- NX CAD’s Simulation and Analysis Tools can be used before product physical prototypes are created, to test how under real-world conditions they perform. This can include, simulating stresses, heat, fluid flow, and other factors, that affect product performance. Designers by identifying potential issues can avoid in the production phase, costly mistakes.

MANUFACTURING:

- NX CAD is also essential tool in the manufacturing process. This includes CAM capabilities. They allow manufacturers to generate for CNC Machines directly from 3D models, toolpaths. The integration between design and manufacturing helps streamline production. This reduces the chances of errors.

CUSTOMIZATION AND PRODUCT VARIANTS: NX CAD

- Helps design products with multiple variants. Or products that need to be for specific clients customized.

Parametric Modeling Tools make it easy to create flexible designs. Designs that can be modified to meet different specifications.

TOOLS AND DIE DESIGN:

- Used in tool and die design. This is critical for industries like aerospace or automotive.

- Provides the requisite tools to create complex tooling geometries and simulate their performance. Also to optimize them for manufacturing.

COLLABORATION AND COMMUNICATIONS:

NX CAD with its cloud-based collaboration tools,

- Facilitates communication between different teams and stakeholders.

- Allows designers to share models and provide feedback. Also to track changes. This ensures everyone involved in the project are on the same page.

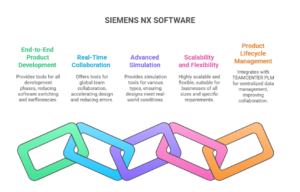

SIEMENS NX SOFTWARE

It’s a complete comprehensive solution. An integrated suite, it includes not just CAD tools but also CAE, CAM, and PLM tools. This comprehensive collection of tools enables organizations to manage within a single platform the entire product development process.

NX CAD Software as part of the broader Siemens NX Software Suite offers for product design and manufacturing, a powerful unified solution. Its deep integration across varied disciplines helps break down silos in the product development process and foster more efficient collaboration.

The following details Siemens NX Software’s advantages

END-TO-END PRODUCT DEVELOPMENT:

- Provides tools to support every phase of product development. From initial concept design to final production.

- Reduces the need for switching between different software programs.

- Eliminates in the design-to-manufacture workflow, inefficiencies.

REAL-TIME COLLABORATION:

- Offers robust collaboration tools. Teams will find it easy to work together. Even if located in different parts of the world.

- Accelerates with real-time collaboration, design process. This reduces errors. And also improves the overall quality of the final product.

ADVANCED SIMULATION:

- Provides powerful simulation and analysis tools. They help ensure designs perform under real-world conditions as expected.

- Supports a wide array of simulation types. This includes structural, dynamics, thermal, and more.

SCALABILITY AND FLEXIBILITY:

- Is highly scalable. This suits small businesses and large enterprises.

- Offers immense flexibility. Essential to scale operations. And, also meet specific design requirements.

PRODUCT LIFECYCLE MANAGEMENT (PLM):

- Integrates with Siemens TEAMCENTER PLM System. This allows companies to manage the entire lifecycle of a product. From initial design to end-of-life.

- Ensures all data is stored in a central repository. This reduces the risk of errors. At same time, also improves collaboration across departments.

NX CAD DESIGN SOFTWARE

It holds the key to innovation. No wonder, it has become a critical tool for driving innovation in different industries. That is, from aerospace to automotive, and consumer goods.

The following tell his it’s shaping product design’s future

ACCELERATING DESIGN PROCESS:

- Equips designers with much needed tools. Tools to create, modify, and optimize designs quickly.

- Allows teams with its powerful modeling capabilities and real-time simulation to make design decisions faster. This helps to bring products to market more quickly.

IMRPOVING PRODUCT QUALITY:

NX CAD helps

- Ensure products meet high standards of quality. Enabling designers to simulate before physical prototypes are made, product performance.

- Enables designers to identify potential issues early in the design phase. This reduces chances of defects. And improve product reliability.

SUPPORTING CUSTOMZIATION:

NX CAD makes it easier for designers to

- Create customized solutions.

- Design and manufacture custom products. Be it designing a consumer electronics product with varied specifications, OR an industrial machine requiring specific modifications.

ENHANCING SUSTAINABILITY:

Helps companies

- Design more sustainable products.

- Reduce waste, minimize energy consumption, and design products easier to recycle. This is possible with simulation and optimization tools.

COLLABORATIVE AND INTEGRATED DESIGN:

NX CAD provides tools that

- Facilitate seamless collaboration. Designers, engineers, and manufacturers can work on a single platform together.

- Facilitate sharing of models and making real-time adjustments. Also, drive discussion on design changes. They improve efficiency and ensure the final product truly reflects the original design intent.

CONCLUSION

The need for an advanced, efficient, and flexible CAD Software is critical even as industries continue to evolve. NX CAD Software herein is a suitable choice. Its comprehensive set of tools with features offers for design, simulation, manufacturing, and collaboration, integrated solutions. This helps companies innovate faster and improve product quality.

Leading NX CAD Software solutions provider CJ Tech has strong proficiency in leveraging Siemens NX Software, and providing results-driven solutions. By leveraging its capabilities, your business can streamline its operations and drive efficient productivity.

FAQs

1. What is NX CAD?

It’s an advanced software suite. Developed by Siemens, it allows designers and engineers to create, simulate, and optimize product designs.

It also helps

- Design complex mechanical parts. And, also assemblies.

- Offer a comprehensive toolset for 3D Modeling and Simulation. Also, for Digital Manufacturing.

2. What for NX CAD Software used for?

It is used

- For different applications in product design. This includes 3D Modeling, Drafting, and Simulation.

- By designers to create highly accurate designs. Also, run simulations to predict performance.

- To streamline product development and manufacturing processes. This ensures high-quality, cost-effective designs.

3. What benefits do I get by using NX CAD Design Software?

NX CAD Design Software offers following benefits.

- ADVANCED MODELING CAPABILITIES: Allows with high precision and flexibility, creation of both 3D and 2D models.

- INTEGRATED SIMULATION TOOLS: Perform stress analysis and fluid dynamics with motion studies within the design process directly.

- COLLABORATION FEATURES: Drives seamless collaboration across departments. Also, with suppliers. Ensures all stakeholders can contribute to the design process.

- EFFICIENT MANUFACTURING: CAD Software integrates with digital manufacturing solutions. They help streamline and optimize production planning.

4. Why should I for product design choose Siemens NX Software?

Siemens NX Software is a standout product.

It

- Offers for design, simulation, and manufacturing, a powerful suite of tools.

- Offers end-to-end solutions. This allows users to cover within a single platform, the entire product development lifecycle.

With Siemens NX, you get tremendous flexibility and scalability. You also get the ability to handle highly complex designs. This makes it for companies in industries needing precision and innovation, a top choice

5. Is NX CAD Software suitable for use by all industries?

Yes. It caters to a wide array of industries. That is, from aerospace to automotive, defense, medical device design, and industrial machinery. Its robust features cater to complex product designs. They also cater to large-scale projects.

6. In what way does NX CAD contribute to product design’s future?

It helps in shaping its future by

- Providing cutting-edge technologies. Like AI-driven design, additive manufacturing capabilities, and advanced simulation tools.

- Allowing engineers to explore new materials and manufacturing techniques.

- Allowing optimization of products. For performance and cost-efficiency.