Aerospace engineering worldwide is among the most complex industries. It is also highly regulated. Aircraft, defense systems, and aviation components need to conform to stringent safety, performance, and compliance norms. Every decision from initial concept development to final certification must be traceable, validated, and backed by precise documentation.

This is where PLM becomes indispensable. PLM Software helps aerospace companies by enabling end-to-end control over product data, engineering processes, and configuration changes, maintain integrity of design; ensure compliance; and guarantee seamless traceability across all stages of the project.

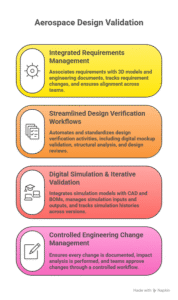

HOW AEROSPACE DESIGN VALIDATION IS SUPPORTED BY PLM?

Design validation plays a highly critical role.

It

- Ensures every engineering output conforms to functional, structural, and regulatory expectations. This includes CAD Model, requirement, subsystem, or prototype.

- Connects teams, data, and workflows. This allows organizations to validate designs efficiently.

INTEGRATED REQUIREMENTS MANAGEMENT

Aerospace projects start with thousands of system and subsystem needs. This requires keeping track of every single requirement. Else it can create design gaps that compromise certification.

PLM Software

- Associates requirements with 3D models and engineering documents,

- Tracks requirement changes. Then ensures alignment across teams.

- Creates bidirectional traceability between requirements and deliverables.

- Ensures every component conforms to system-level expectations.

This helps to

- Prevent requirements mismatches; and

- Ensure design intent is throughout the lifecycle preserved.

STREAMLINED DESIGN VERIFICATION WORKFLOWS

PLM offers structured workflows. They automate and standardize design verification activities.

PLM verification workflows include:

- Digital mockup validation.

- Structural analysis. Like integration with CAE tools.

- Design reviews.

- Fit-and-function checks.

- Safety and compliance validations.

Aerospace teams ensure with consistent workflows that every design milestone is reviewed, validated, and documented.

DIGITAL SUMULATION & ITERATIVE VALIDATION

Aerospace validation relies heavily on simulation. This includes

- Thermal analysis;

- Aerodynamic models;

- Stress testing;

- Fatigue analysis; and more.

Teams by using PLM can:

- Integrate simulation models with CAD and BOMs.

- Manage simulation inputs and outputs.

- Track simulation histories across versions.

- Validate performance early in the design cycle.

Early simulation integration helps

- Reduce physical testing costs; and

- Accelerate development timelines.

CONTROLLED ENGINEERING CHANGE MANAGEMENT

Design modifications in aerospace development are inevitable. But uncontrolled changes can introduce safety errors. They can also cause compliance issues.

PLM helps ensure

- Every change is documented.

- Impact analysis is performed.

- Teams approve changes through a controlled workflow.

- Updated designs stay traceable to earlier versions.

They help to

- Keep engineering consistent; and

- Avoid configurations conflicts’.

ENSURING TRACEABILITY WITH PLM

ENSURING TRACEABILITY WITH PLM

Traceability is a vital part of aerospace certification. Regulators seek transparency into how a product was designed, tested, manufactured, and validated. This is where PLM helps. It enables this process through a unified, digital thread. This thread connects every engineering action, from concept through to retirement.

COMPLETE LIFECYCLE TRACEABILITY (DIGITAL THREAD)

A continual flow of connected data is maintained by PLM across:

- Requirements;

- Design;

- Engineering Analysis;

- Manufacturing;

- Quality Checks; and

- Maintenance History.

This digital thread enables seamless traceability. This is essential for audits, certifications, and internal reviews.

CONFIGURATION MANAGEMENT AT EVERY STAGE

Aerospace products evolve across multiple configurations. This includes prototypes, pre-production models, certified versions, and fielded units.

PLM Software ensures:

- Accurate versioning;

- Approved configurations are controlled; and

- Preservation of historical configurations for audits.

All stakeholders work on the latest data. This helps to prevent errors resulting from outdated or conflicting models.

SUPPLIER TRACEABILITY & COLLABORATION

Aerospace supply chains involve hundreds of suppliers.

These suppliers engage in producing

- Structural parts;

- Avionics modules;

- Wiring systems; and

- Software components.

PLM supports:

- Data traceability across multi-tier suppliers.

- Secure collaboration through controlled data access.

- Standardized document exchange.

- Tracking of supplier performance and compliance.

This helps to

- Improve supply chain reliability; and

- Ensure all components meet aerospace norms.

COMPLIANCE & CERTIFCIATION DOCUMENTATION

Regulatory bodies require detailed documentation. This is required for airworthiness certification.

PLM automatically organizes:

- Engineering drawings.

- Test reports.

- Change logs.

- Requirements verification matrices.

- Compliance checklists.

Aerospace companies with centralized documentation will be able to

- Reduce audit time and

- Accelerate certification readiness.

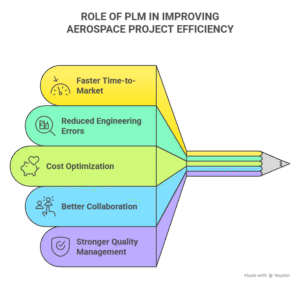

ROLE OF PLM IN IMPROVING AEROSPACE PROJECT EFFICIENCY

PLM offers beyond validation and traceability, multiple operational advantages.

Like,

Like,

FASTER TIME-TO-MARKET: PLM facilitates overall development by

- Preventing rework;

- Eliminating data silos; and

- Automating workflows.

REDUCED ENGINEERING ERRORS: Unified data and automated validation

- Minimizes to a significant extent chances of design inconsistencies.

- Ensures design consistency is maintained to the maximum extent.

COST OPTIMIZATION: Early identification of design issues

- Prevents chances of rework; and

- Saves certification costs.

BETTER COLLABORATION ACROSS TEAMS:

- Brings together teams from engineering, manufacturing and quality; and suppliers.

- Facilitates seamless collaboration on a shared digital platform.

STRONGER QUALITY MANAGEMENT:

- Identifies early quality issues with real-time visibility into engineering processes

WHY AEROSPACE ORGANIZATIONS NEED PLM SERVICES?

PLM is unlike other software. It is extremely sophisticated and complex software that needs more than just mere software installation. It also requires efficient process transformation, integration, and change management. This is where PLM services become critical. Aerospace companies can best leverage PLM services with the help of PLM experts.

They stand to benefit from:

- PLM strategy and roadmap development.

- Implementation and customization.

- Data migration.

- Integration with CAD/CAE/ ERP tools.

- Change management and user training.

- Maintenance and support.

Aerospace companies can by enlisting the expertise of specialized PLM service providers, leverage PLM’s capabilities to the maximum. This will help them achieve digital transformation.

HOW TO CHOOSE THE RIGHT PLM SOFTWARE?

Not all PLM systems are created equal. They differ from system to system.

Aerospace companies require PLM software that supports:

- Complex requirements;

- Multi-tier supply chains; and

- Mission-critical validation workflows.

PLM Software should ideally offer:

- Requirement Management;

- Multi-disciplinary Design Control;

- Simulation & Digital Twin Support;

- Safety & Compliance Workflows;

- Advanced Configuration Management;

- Supply Chain Collaboration; and

- Strong Integration with CAD/CAE/ERP tools.

Selecting the right platform will significantly benefit aerospace teams. They can operate with maximum efficiency, transparency, and control.

CONCLUSION

Aerospace projects are extremely complicated. They demand the highest levels of precision and compliance with systems engineering discipline.

PLM Software offers the digital infrastructure required to

- Validate designs;

- Manage complex configurations; and

- Ensure traceability across the entire lifecycle.

Organizations can by leveraging CJ Tech’s expert PLM services, deliver safer, and more reliable aerospace products. They can simultaneously meet global regulatory norms and accelerate innovation.

FAQs

1. How is traceability in aerospace projects improved by PLM Software?

PLM Software offers end-to-end traceability.

This is achieved in one unified environment by linking

- Requirements;

- CAD Models;

- Simulations;

- Test reports;

- Change requests; and

- Documentation

Aerospace engineers as a result of this can track every design and change back to its originating requirements. This helps improve transparency and audit readiness.

2. How are design validation processes supported by PLM?

Design validation is ensured by PLM in the following manner.

- Managing requirement-to-design relationships.

- Enforcing standardized engineering workflows.

- Controlling versions and revisions.

- Integrating CAD, CAE, and Simulation Tools.

- Capturing validation evidence and approvals.

This structured approach ensures aerospace designs conform to all norms-regulatory, safety, and performance.

3. How is collaboration between cross-functional aerospace teams enhanced by PLM?

PLM centralizes data. This allows

- Teams-engineering, manufacturing, procurement, and quality, to collaborate in real-time.

- Users to access the latest design the latest design updates; review documents; and share feedback through the integrated workflows.

Thus, they help reduce rework and communication delays.

4. What role does PLM Services play in aerospace design validation?

PLM Services include consulting; implementation; customization; integration; and support.

These services help aerospace companies:

- Configure PLM platforms for their validation processes.

- Integrate PLM with CAD/CAE, ERP, and Testing Tools.

- Automate traceability and compliance workflows.

- Train users’ and optimize system performance

5. How is the accuracy of version control and change management ensured by PLM?

PLM offers automated versioning, revision, control, and change management workflows. Now when a design update happens, the system logs the change. Then captures the rationale, and later notifies stakeholders. They also maintain a complete audit trail.

This will help prevent unauthorized modifications. At the same time, also ensure consistency across teams.

ENSURING TRACEABILITY WITH PLM

ENSURING TRACEABILITY WITH PLM Like,

Like,